| Working Voltage | 24V, 110V, 240V |

| Test Load | 85N |

| Max. Working Temp. | 90°C |

| Min. Load | 45N |

| Max. Load | 140N |

| Stoke | 3.8 ± 0.1 mm |

* based on practical test data

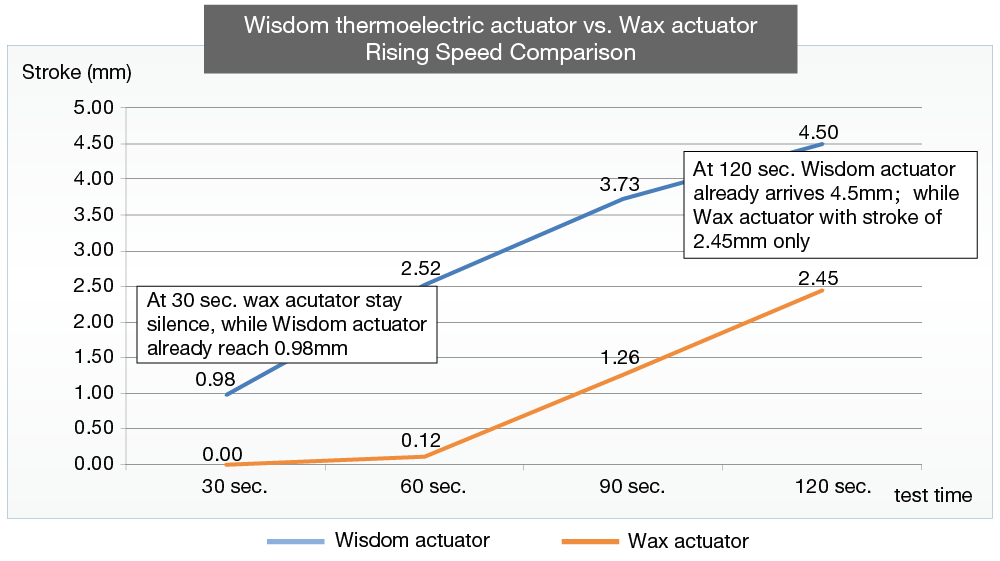

Test 1: Stroke Speed Test

Test two groups of Wisdom actuators and Wax-made ones, with 80N load, heating 6400ohms PTC resistance from +20°, record stroke height every 30 seconds.

Test result: at 30 sec. wax acutator stay silence, while Wisdom actuator already reach 0.98mm; at 120 sec. Wisdom actuator already arrives 4.5mm;while Wax actuator with stroke of 2.45mm only. In summary, Wisdom thermal actuators are rising much more rapidly than wax-made products.

Left: Wisdom actuator; right: Wax actuator

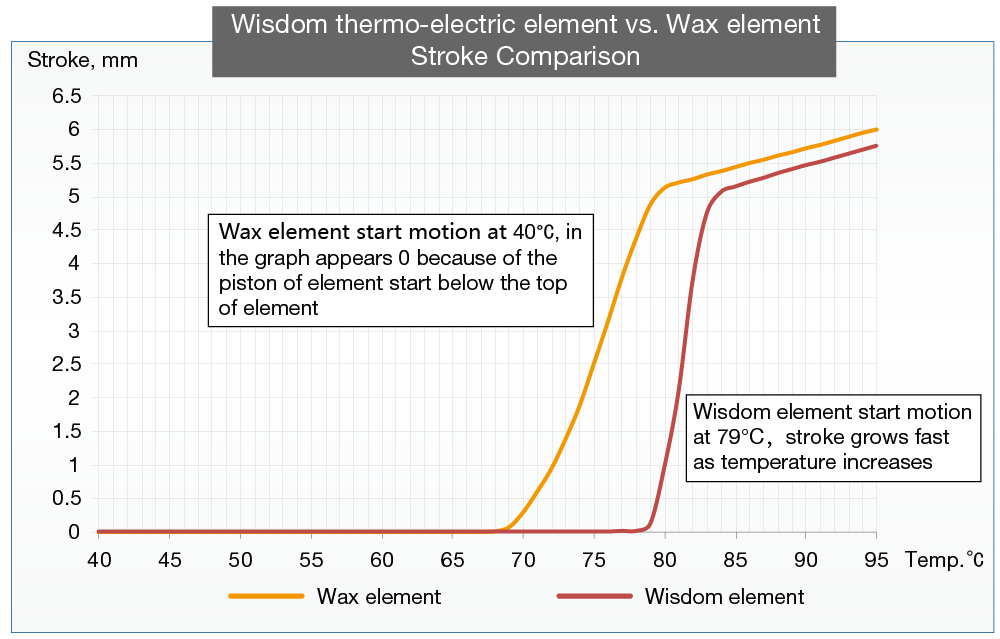

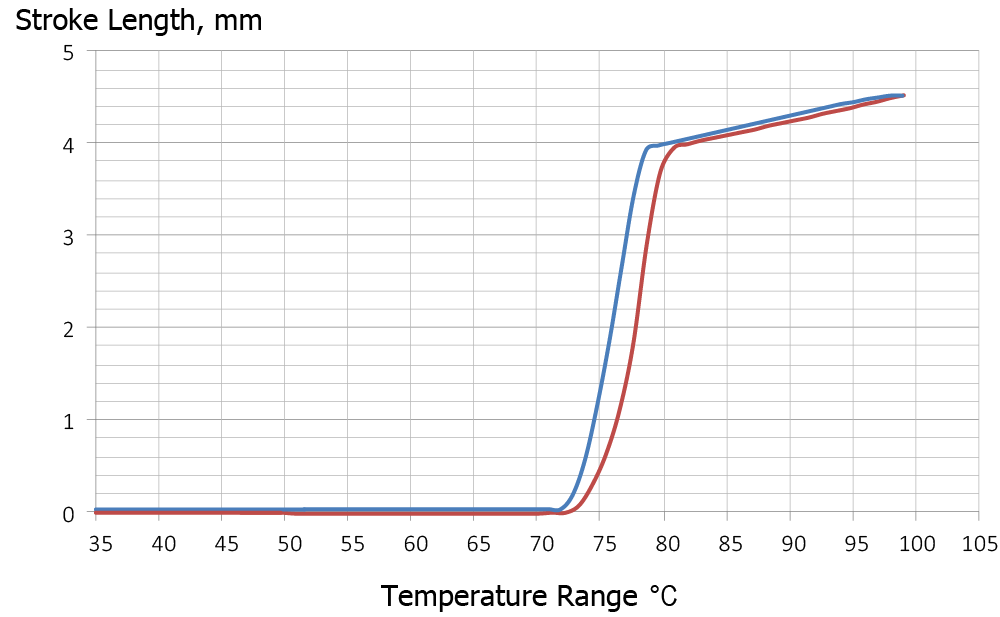

Test 2: Temperature - Stroke Comparison

Test two groups samples starting from 30°C till 90°C, with load of 80N. The stroke – temperature curve as below:

Summary 1): wax element start actually generating motion at 40°C; note that the piston beneath the element top.

Summary 2): Wisdom element start motion at 79°C, and grow stroke quite fast: between 79°C to 84°C, the element piston grows 5mm; while wax element grows 5.2mm between 69°C to 79°C. Wisdom element significantly faster than wax element as temperature incresses.

Left: Wisdom actuator; right: Wax actuator