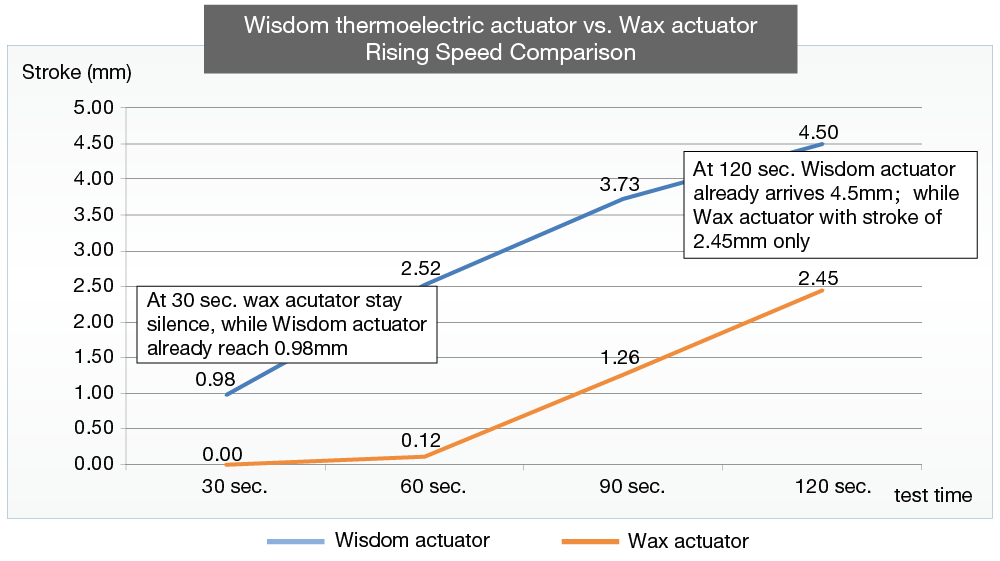

Test 1: Stroke Speed Test

Test two groups of Wisdom actuators and Wax-made ones, with 80N load, heating 6400ohms PTC resistance from +20°, record stroke height every 30 seconds.

Test result: at 30 sec. wax acutator stay silence, while Wisdom actuator already reach 0.98mm; at 120 sec. Wisdom actuator already arrives 4.5mm;while Wax actuator with stroke of 2.45mm only. In summary, Wisdom thermal actuators are rising much more rapidly than wax-made products.

Left: Wisdom actuator; right: Wax actuator

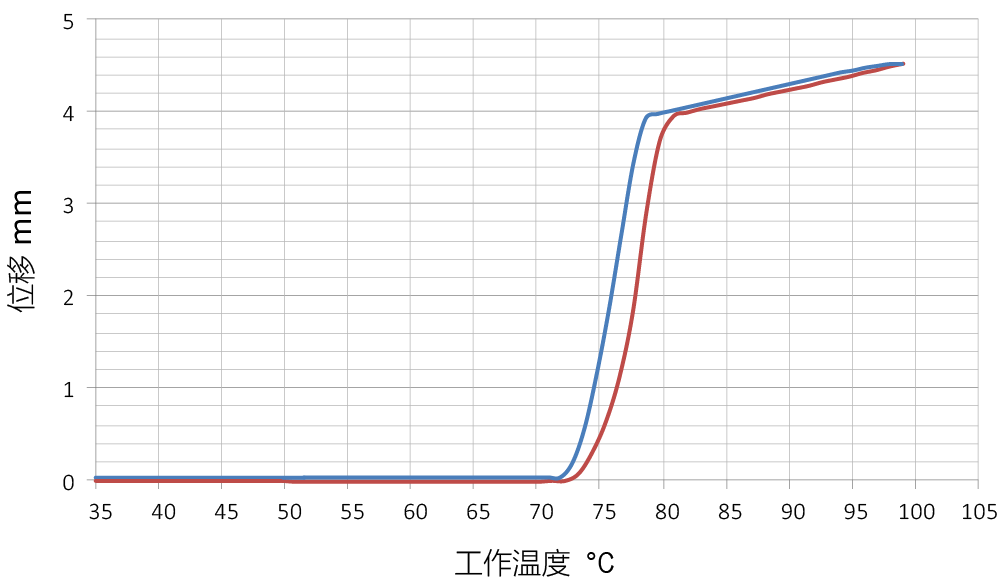

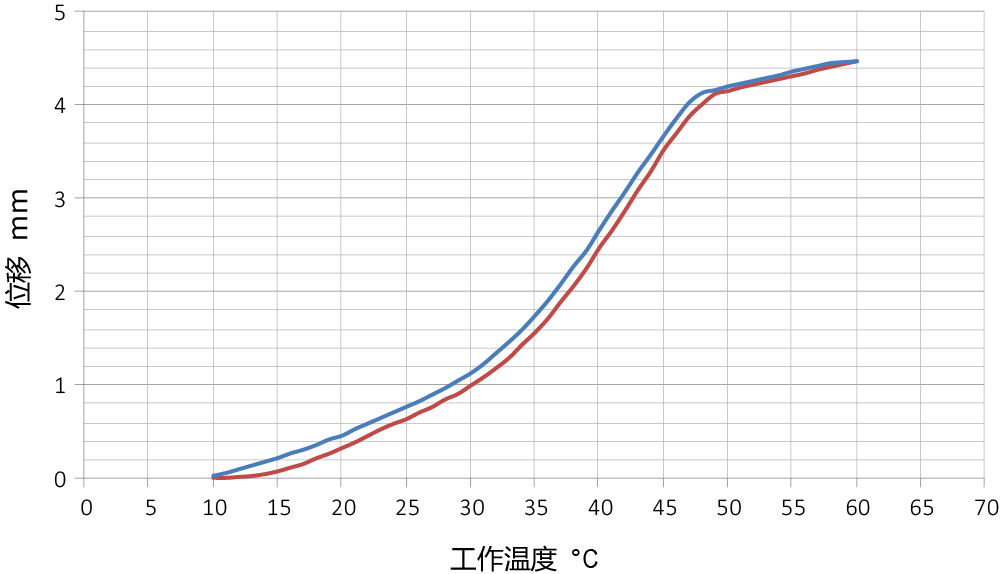

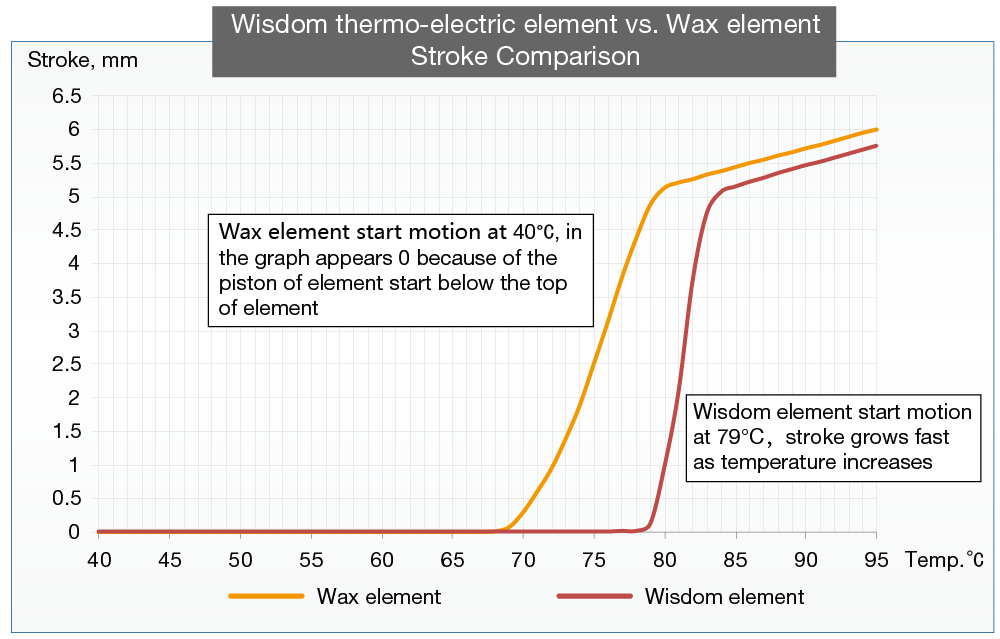

Test 2: Temperature - Stroke Comparison

Test two groups samples starting from 30°C till 90°C, with load of 80N. The stroke – temperature curve as below:

Summary 1): wax element start actually generating motion at 40°C; note that the piston beneath the element top.

Summary 2): Wisdom element start motion at 79°C, and grow stroke quite fast: between 79°C to 84°C, the element piston grows 5mm; while wax element grows 5.2mm between 69°C to 79°C. Wisdom element significantly faster than wax element as temperature incresses.

Left: Wisdom actuator; right: Wax actuator

* Above samples tested are of automobile engine thermal control element, with 80N test load, started by ambient temp. 20°C.

test (1): put samples into 40°C water, it takes 4min 9sec. to reach stroke of 8mm; while wax-made element need 11min. more。

test (2): put samples into 50°C water, it takes 1min 46sec. to reach stroke of 8mm; while wax-made element need 9min. more。

test (3): after samples reach the max. stroke, put them into 15°C water and record, it takes 20sec. return.