Thermostatic elements (thermal actuators) are a kind of devices that output mechanical movement, as the feedback of their surrounding temperature change.

The thermally sensitive material inside those elements can be expanded widely due to temperature increasing, it produces pressure or extrusion toward a piston generating movement.

The movement / motion of these thermostatic elements can be used to operate valves or mechanical switches, etc. without any electrical power. Therefore they can be applied in various of applications e.g. automotive, thermal air vent, sanitary ware, heating, etc.

Advantages of Wisdom new thermostatic technology

- High expansion rate

- Supreme load strength

- Improved stroke length

- Great control accuracy

- Maintenance-free

- No need electrical power

- Long service life

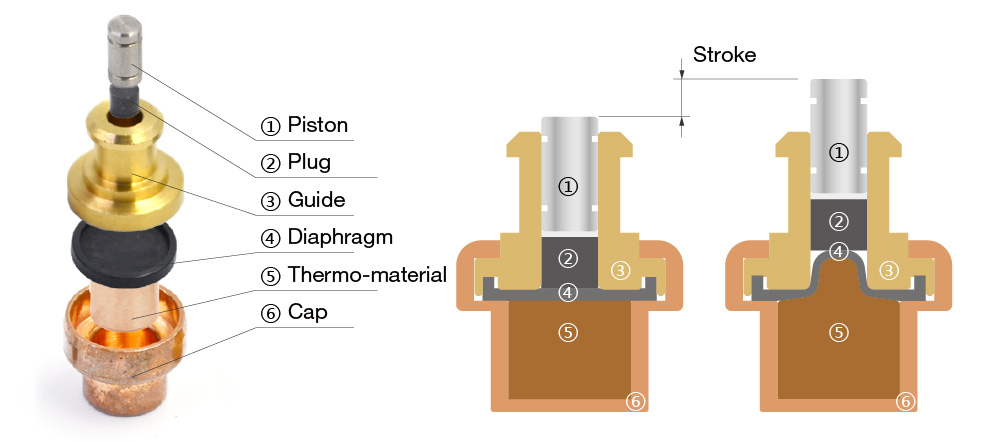

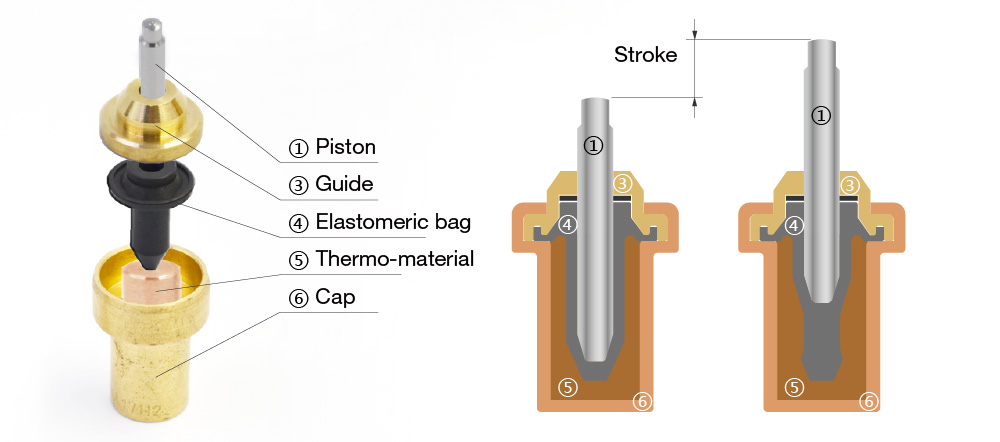

There’re two types of structure for thermal actuators: Diaphragm type and Squeeze-push type.

When the temperature outside the cap ⑥ increases, thermal material ⑤ expands and extrudes the diaphragm ④; diaphragm ④ push plug ②, causes the movement of piston ① .

When the temperature outside cooling down, a load pushes back on the piston, resets the system for next cycle.

Advantage: precise movement, high sensitivity.

When the temperature outside the cap ⑥ increases, thermal material ⑤ expands and extrudes elastomeric bag ④ to push piston ①, forces piston ① for movement.

When the temperature outside cooling down, a load pushes back on the piston, resets the system for next cycle.

Advantage: precise movement, high sensitivity.