This paper introduces the elevator control system with PIC single chip computer as the core part.

The control system sends out the command signal by identifying the level change caused by the press of the key. The system processes the command signal and controls the elevator to operate accordingly. When the elevator fails, the system controls the motor to brake urgently. The fault elevator is positioned and alarmed remotely through GPS assistant alarm mechanism, and the fault information is sent to the control center for processing. The controller can meet the design requirements of stability and safety in elevator control. In this paper, modular design method is adopted to facilitate maintenance and function expansion. The system hardware block diagram, program flow chart and operation results are given.

At present, the control of elevator mainly adopts relay, PLC and single chip computer. The disadvantages of relay control system are complex circuit, high failure rate, which greatly reduces the reliability and safety of elevator.

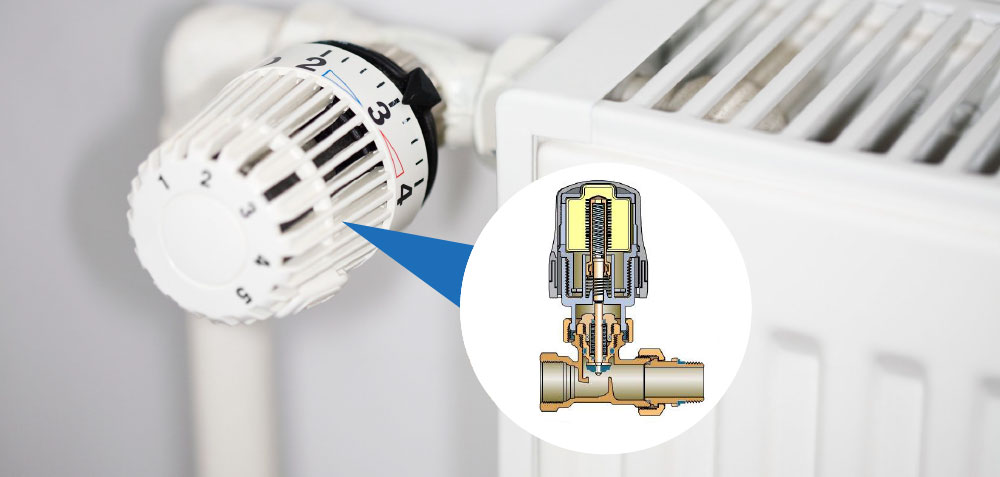

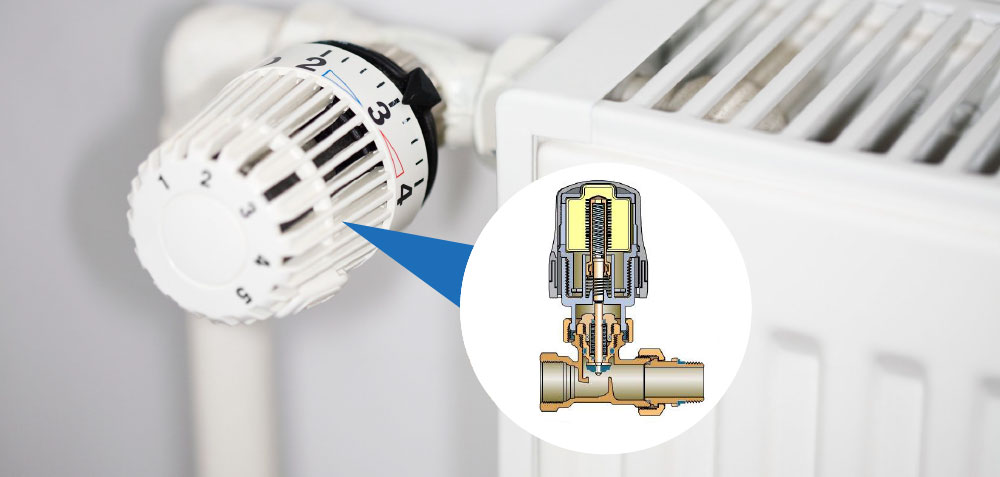

PLC programmable controller uses programmable instructions and ladder diagram control mode, thermostatic element which is easy to use, stable performance and easy to master. It has been widely applied in elevator control system. The disadvantage is that it is difficult to upgrade and expand, the cost is relatively high, and it is difficult to meet the real-time upgrade control requirements under the network control environment. Therefore, it is necessary to develop a control mode based on security, high efficiency, easy expansion and low cost. The characteristics of the single-chip computer control system are that the system is stable, reliable, the cost is greatly reduced, the upgrade and expansion are convenient, and it is easy to realize multi-computer and distributed control under the network control environment. Making [1-2]. The structure of the system is shown in Figure 1. The stepping motor is driven by L298N. As shown in Figure 4, the stepping motor is an open-loop control element that converts the electric pulse signal into angular displacement or linear displacement. In the case of non-overload, the speed and stop position of the motor only depend on the frequency and pulse number of the pulse signal, but not affected by the change of the load. The angular displacement is controlled by controlling the number of pulses, so as to achieve the goal of accurate positioning. At the same time, the speed and acceleration of the motor can be controlled by controlling the pulse frequency to achieve the goal of speed regulation. In the process of program design, the operation process of the motor is divided into three stages: acceleration, uniform speed and deceleration, as shown in Fig. 5.

PWM signal is set according to MCU system program, and different signals are produced by pressing different keys to realize the positive and reverse of the motor, so as to control the elevator lifting and the opening and closing of the elevator door.

There are abnormal alarm buttons in the bridge compartment. When abnormal conditions occur, passengers press the emergency alarm button, the system control mechanism brakes, buzzer alarms, and the GPS module starts to work. The circuit of the GPS positioning module is shown in Figure 6. The positioning information is sent to the control center after processing. The alarm circuit is shown in Figure 7. The pressure sensor is installed at the bottom of the bridge compartment, and the collected gravity data is transmitted to the single chip computer through A/D conversion for processing [6-8]. If overweight occurs, the buzzer will send out an alarm signal. At the same time, the buzzer will collect data every three seconds. When the load is within the safe range, the buzzer will stop alarming and the elevator will start running. As shown in Figure 8, this part of the circuit makes a request to the user in the elevator. R1-R7 is pull-up resistance. When not pressed, the RB0-RB6 ports are high level. When the button is pressed, the port becomes low level.

S1-S3 represents going to the 1st, 2nd, 3rd and 4th floor respectively. When pressing S4, the elevator door opens. When pressing S5, the elevator door closes. S7 is an alarm button. When the elevator fails, pressing this button will trigger the elevator alarm. The control system is based on PIC16F877 microprocessor. The program is written in C language [9]. The initialization of the system is completed by the main program. The other parts are mainly controlled by subroutines. The design flow chart is shown in Fig. 9. With PIC16F877 chip as the core hardware system, elevator operation is controlled by keys. When no key is pressed, the key is scanned every 3 seconds to detect whether there is a request. When there is a request, the corresponding low level is sent to the single-chip computer for processing. The single-chip computer makes a logical judgment according to the fault, the position of the current elevator, the number of floors between the target floor and the current floor, decides whether the elevator is running or not and the direction of operation; adjusts the speed of the motor through the output of the duty cycle of PWM; Fig. 10 shows the information of the elevator from the second floor to the fourth floor; Fig. 11 shows the information of the fourth floor. When the elevator fails, the controller controls the braking of the elevator and starts the GPS module. The GPS starts positioning and the alarm gives an alarm. The fault information is shown in Figure 12.

GSM sends the positioning information and the fault elevator code to the control center through the wireless terminal. After testing, the system runs stably, responds promptly, achieves the expected goal, has good market prospects and high application value.