From October 1, 2015, Nord Drive Group will change its design and install new and more flexible microcontrollers and firmware in all motor and cabinet-mounted converters.

It is noteworthy that this structural upgrade enables the frequency converter originally designed for asynchronous motors to control synchronous motors.

With the advent of IE4 high-efficiency and energy-saving motors, this has become increasingly important. Now, even in the absence of encoder feedback, the converter can perform high dynamic driving tasks. Its substantial advantage is that customers who have been using IE3 motors with encoders can save energy and cost by switching to IE4 motors without encoders.

In addition, Nord’s new generation converter can also perform drive-related PLC functions, which significantly reduces the use of external controllers. In some cases, previously used small controllers may become redundant and completely omitted. The converter supports the independent PLC open motion control function block of the manufacturer.

It can program freely according to the “structured text” or “instruction list” in IEC 61131-3, which simplifies the development of application program and reduces the related cost. Customer-specific driver-related functions can be implemented by the programmable controller of the frequency converter without using specific application firmware, and cost-intensive verification is omitted.

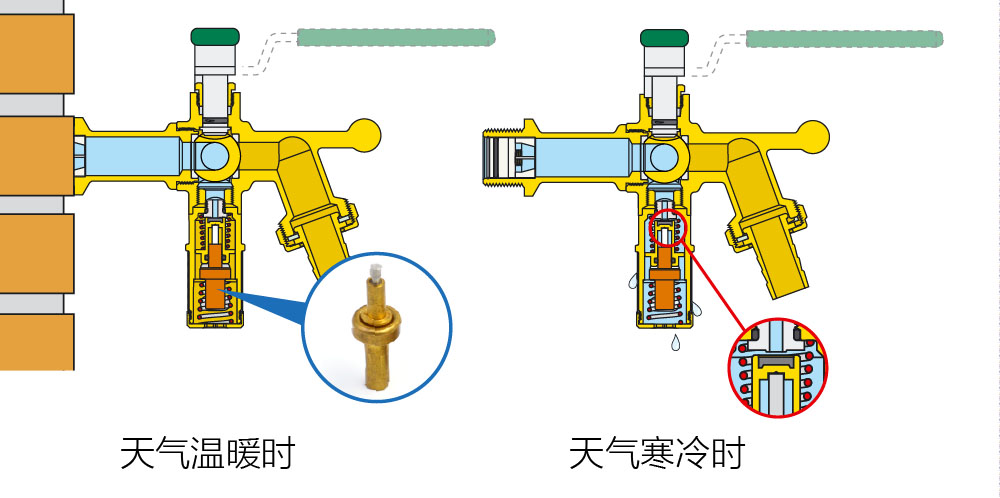

As the developer and manufacturer of transmission technology, Node Drive Co., Ltd. has 3,000 employees and is one of the world’s leading suppliers of comprehensive drive solutions. Nord’s product range includes standard drives and customized solutions with stringent application requirements, thermostatic element such as energy-saving or explosion-proof drives.

Nord’s total sales in 2014 were about 500 million euros. Nord was founded in 1965 and currently has 36 subsidiaries worldwide. It has established a huge distribution and service network to ensure the shortest delivery time and provide customer-oriented services in the shortest possible time. Node’s various transmission devices have a torque range of 10-242 000 N.

m.

At the same time, it produces motor with output power of 0.12-1 000 kW and electrical control devices including frequency converter and servo controller. Nord Inverter Series includes both the traditional models installed in the control cabinet and the design models that can fully integrate the drive devices into the distributed automation environment.