Intelligent vehicle is an integrated system which integrates environmental awareness, planning and decision-making, multi-level driving assistance and other functions.

This paper takes Freescale Cup National College Students Intelligent Vehicle Competition as the research background, using Freescale 32-bit microcontroller MK60DN512ZVLL10 as the core control unit. The system realizes the tracking motion of the intelligent car under complete hardware conditions through the control of microcontroller.

In hardware aspect, hardware circuits including power supply module, single chip module, LCD module and driving module should be designed by ourselves to complete the tasks of speed control and steering control. The control algorithm is studied from PID to Bang-Bang.

Through the rational layout of hardware, the rational planning of circuit, the rational configuration of machinery, the reasonable and feasible software algorithm, the design of intelligent car finally succeeded. In the design, the mechanical performance, electrical performance, system software, reliability, appearance, installation and maintenance of the system are considered.

The system uses Freescale MK60DN512ZVLL10 MCU as the detection and control core, linear array CCD as the path detection sensor, according to the track information detected by CCD and the car speed and balance information, the car is steered and controlled by software. The Intelligent Vehicle System uses Freescale’s 32-bit microcontroller MK60DN512ZVLL10 as the core control unit to control the Intelligent Vehicle System. Linear CCD and LED are selected as sensors of photoelectric vehicle. Linear CCD collects track light and shade information and returns to MCU as the basis of steering control. In order to make the car run on the specified track, the main control outputs PWM wave. By adjusting the duty cycle of PWM wave, the speed of motor and steering gear are controlled to lock the track. Let the car run as smoothly as possible in the middle of the track. In order to control the accuracy and rapidity, we use the encoder as the speed sensor. The signal returned by the encoder can form a closed loop, using PID to control the steering of the steering gear and the speed of the motor. The whole debugging process is to continuously improve the average speed of the vehicle model on the premise of ensuring the stable track of the body. In the design of hardware circuit, the whole system is divided into several modules, such as minimum system board, signal acquisition module and signal preliminary processing module.

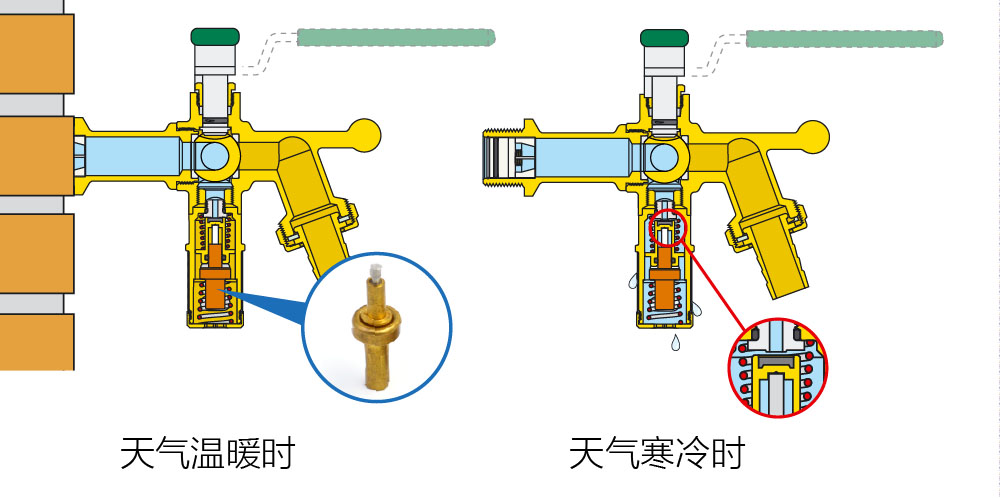

Each module is only responsible for completing specific functions and is relatively independent from other modules. The car consists of six modules: MK60DN512ZVLL10 main control module, thermostatic element sensor module, power module, motor drive module, speed detection module and auxiliary debugging module. As shown in Figure 2. Auxiliary debugging module is mainly used for function debugging of intelligent vehicle system and condition monitoring of racing car. K60 chip comes with Flash memory. Adding auxiliary debugging module can change its parameters in real time, which makes the debugging process more convenient.

The LCD module is used to display the parameters of the car, and the keyboard and dial switch are used to adjust the parameters that need to be changed.

K60 converts the analog signal collected by CCD into digital signal. Through simple calculation, the current position of the car can be determined. Then the current speed of the car can be calculated according to the numerical value transmitted by the photoelectric encoder. Based on the above two values, the position deviation and speed change of the car can be calculated. Through the position deviation and speed change of the car, the steering of the car is controlled by the steering gear PID, and the motor speed is controlled by the speed PD, so that the car can run smoothly and correctly on the track.