The installed capacity of the 25MW power plant of Kungang Power and Energy Branch is 25MW. It has been 8 years since it was built and put into operation in 2005. Its mechanical speed regulating feedback component, spring, has been deformed due to frequent operation at high temperature for a long time. Since 2010, the normal regulation of the steam turbine has been affected, resulting in the load of the generating unit not reaching the rated value. After several rectifications in the control workshop and thermoelectric workshop, the steam pressure and flow are sufficient. In this case, the rated power of 25 MW generators can only be brought to 20 MW, which seriously affects the economic benefits of branch companies. Based on the application of 505 electric regulation system in 18MW, 3rd and 4th firing generators of the branch company, the regulation system of 25MW generators has been reformed with the agreement of the branch company of Thermoelectric Workshop Research Report. The original mechanical speed regulation system has been changed to 505 electric control system. The oil circuit of the former mechanical speed regulation feedback component-spring has been reformed by the thermal power workshop, and the 505 instrument installation and wiring have been carried out in the planning and control workshop. The automatic control configuration combined with DCS of 25MW power station realizes automatic start-up and shutdown of steam turbine generator set. The installed capacity of the 25MW power plant of Kungang Power and Energy Branch is 25MW. It has been 8 years since it was built and put into operation in 2005.

Its mechanical speed regulating feedback component, spring, has been deformed due to frequent operation at high temperature for a long time.

Since 2010, the normal regulation of the steam turbine has been affected, resulting in the load of the generating unit not reaching the rated value. After several rectifications in the control workshop and thermoelectric workshop, the steam pressure and flow are sufficient.

In this case, the rated power of 25 MW generators can only be brought to 20 MW, which seriously affects the economic benefits of branch companies. Based on the application of 505 electric regulation system in 18MW, 3rd and 4th firing generators of the branch company, the regulation system of 25MW generators has been reformed with the agreement of the branch company of Thermoelectric Workshop Research Report. The original mechanical speed regulation system has been changed to 505 electric control system.

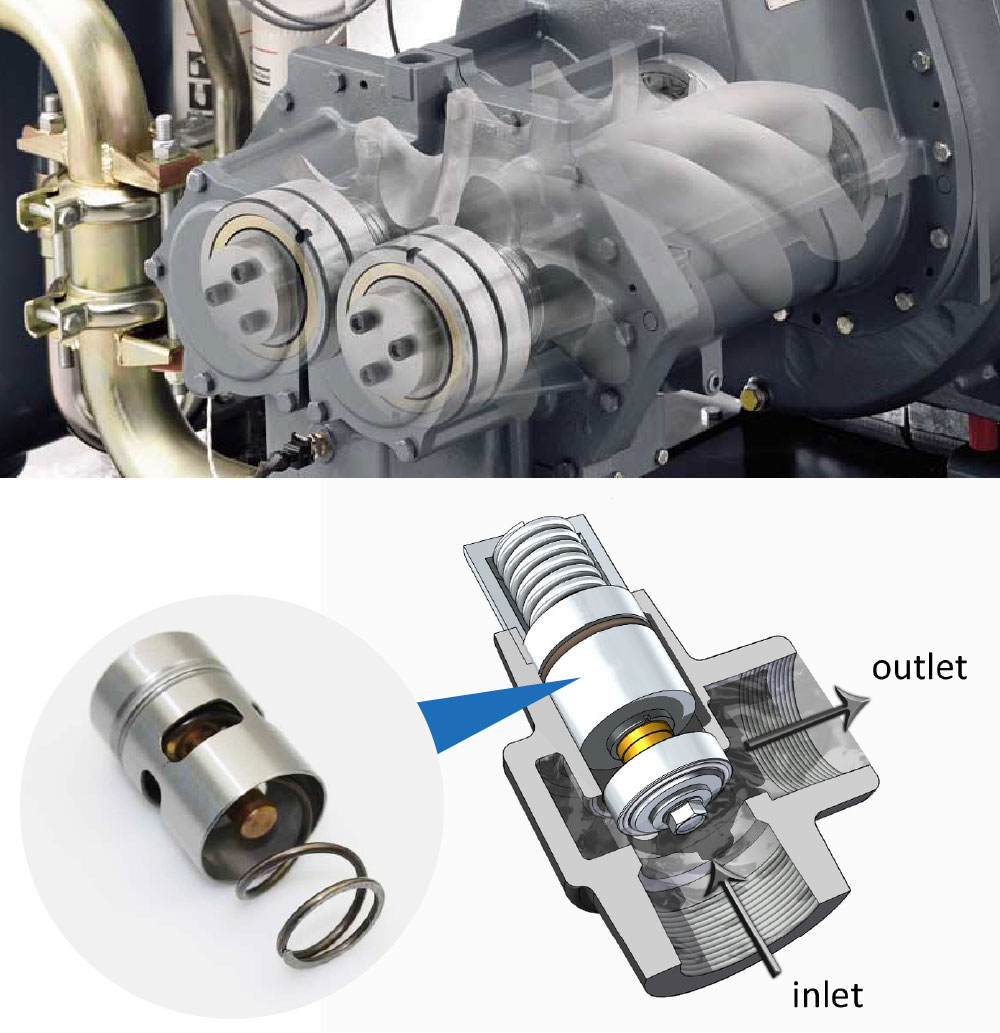

The oil circuit of the former mechanical speed regulation feedback component-spring has been reformed by the thermal power workshop, and the 505 instrument installation and wiring have been carried out in the planning and control workshop. The automatic control configuration combined with DCS of 25MW power station realizes automatic start-up and shutdown of steam turbine generator set. The DEH control system of MW generating set adopts the 505 controller of WOODWARD Company (hereinafter referred to as 505) and the SPC servo controller to complete the steps of data acquisition, control, monitoring and manipulation. DEH control system is composed of DEH control cabinet, EH hydraulic part sleeve, DDV servo valve, LVDT displacement sensor, magnetoresistive sensor, oil motor and so on. 505 completes on-site signal acquisition, control and monitoring, diagnostic results, early warning shutdown, various test manipulation.

The SPC servo controller receives 4-20mA valve position instruction signal from 505, and receives feedback signal from LVDT displacement sensor, and outputs – 10mA?- 10mA instruction signal to DDV servo valve. DDV servo valve receives the instruction signal of – 10mA?- 10mA from SPC servo controller, adjusts the pulse oil pressure, and realizes the effective control and protection of the turbine regulating valve through the action of the oil motor. LVDT displacement sensor is a linear differential transformer displacement sensor. It mainly measures the stroke of the oil engine and feeds back the measured signal to the SPC servo controller.

Press PRGM key on 505 operation panel to configure, set corresponding parameters and input and output functions according to need, and at the same time, through RESET, RUN, STOP buttons on 505, can start and stop the generator set. Through the configuration of 505 controller, the turbogenerator can automatically start and stop according to the graph below, and automatically increase and reduce load (power). According to the pre-set configuration, 505 carries out low-speed and high-speed warm-up at 500 and 1100 revolutions, and calculates the warm-up time of T1 and T2 according to the length of shutdown time.

1400-2500 is the critical speed belt. In each speed-up stage, the generator set is accelerated according to the pre-set speed-up. During the critical speed band, the vibration of the generator set increases and the unit speeds up rapidly. When the unit speed reaches 3000 revolutions/minutes, the grid-connected power generation can be carried out. During the rush process, when the speed of the generator reaches 3180 revolutions/minutes, the 505 over-speed protection jumper (the generator set is dragged by the grid during the grid-connected power generation process, it will not exceed 3.8 revolutions/minutes). 000 rpm/min.

Warming time and speed automatic warmers and speed-up can also be used to protect and shut down the electric adjusting device. Reset, run, stop, speed up/down buttons on the controller can also be configurated into DCS control screen for operation.

As shown in the following figure, the operation button is set on the operator’s panel through the configuration of DCS lower program, and the corresponding control command is issued to 505 through the lower controller. In the control screen, the operator can see the relevant oil motor stroke, pulse oil pressure, generator power, DDV valve position, the speed of sluice hydraulic turbine, alarm signal of electric adjusting device, alarm signal of SPC servo controller, etc. The button can be used for SPC reset, 505 reset, 505 operation, speed rise/fall, sluice solenoid valve and OPC solenoid valve operation.

When satisfying the condition of turbine’s rush, the operator first resets the turbine, then opens the electric main valve and the automatic main valve. After confirming the normal operation, press SPC reset and 505 reset to clear all alarm and stop signals, then press the operation button, the oil engine automatically opens and 505 enters the speed control. The unit completes the cold/hot state heater, over-critical until 3000r/min grid-connected power generation according to the pre-configuration procedure. 。 Because the 505 controller integrates the advantages of digital electronics and hydraulic technology, i.e. electronic command and hydraulic action, it has a series of advantages, such as good regulation quality, fast dynamic response, high control accuracy, easy operation of the system and easy realization of integrated automation, etc. Therefore, the renovation of oil system of 25MW generating unit is determined. Power Energy Branch 25MW waste heat and residual energy power station uses surplus gas to generate electricity reasonably, and generates more electricity is our consistent goal. It is also an important part of the company’s “cost reduction, innovation and efficiency”. As shown in the following figure, after adopting 505 digital electric control system, the load control of 25MW generating unit is obviously superior to the manual control before the transformation, because of the improvement of system sensitivity and automation level. The operation is simple and the automation level is greatly improved, which makes the load of generating unit reach the rated value of 25MW. According to this normal situation, more than 5,000 KW/h of electricity is generated per hour and at least 120,000 KW/h of electricity is generated per day. Each year, 43.8 million KW/h of electricity will be generated, calculated at a market price of 0.45 yuan per hour, thermostatic element which will bring about an annual economic benefit of 19.71 million yuan for the company. From the perspective of human resource potential tapping, before the transformation, the operator needs 2 people to start the machine, 1 person to operate locally, and 1 person to monitor and command indoors. After the transformation, only one person is required to operate indoors, which greatly saves human resources and a lot of labor costs. Therefore, the 505 power regulation renovation of 25MW power station is successful.