Programmable Logic Controller (PLC) is abbreviated as PLC.

Its function in mine electromechanical control is mainly to control, calculate, record and operate the electromechanical logic situation by using the memory of programmable logic controller. This is mainly accomplished by transmitting in digital form or mode. Because of its convenience and reliability, more and more programmable logic controllers are used in the electromechanical control of coal mines. Microprocessors appeared in the early 1970s. It was introduced into the programmable logic controller (PLC) quickly, which added the functions of operation, data transmission and processing, and completed the industrial control device with computer characteristics.

At this time, the programmable logic controller is the product of the combination of microcomputer technology and conventional control concept of relay. Programmable Logic Controller (PLC), which uses a kind of programmable memory for its internal storage program, executes user-oriented instructions such as logic operation, sequence control, timing, counting and arithmetic operation, and controls various types of machinery or production processes through digital or analog input/output. Programmable Logic Controller (PLC) is a kind of device which can control various types of machinery or production process by using memory which can store and execute logic operation, sequential operation, timing and arithmetic operation programming and other related contents in industrial environment. In terms of structure, there are two kinds of programmable logic controller: fixed atmosphere controller and combined controller.

Fixed controller includes CPU board, I/O board, display panel, memory block, power supply, etc. These parts are indispensable. The combined controller includes CPU module, I/O module, memory module, power module, floor or rack.

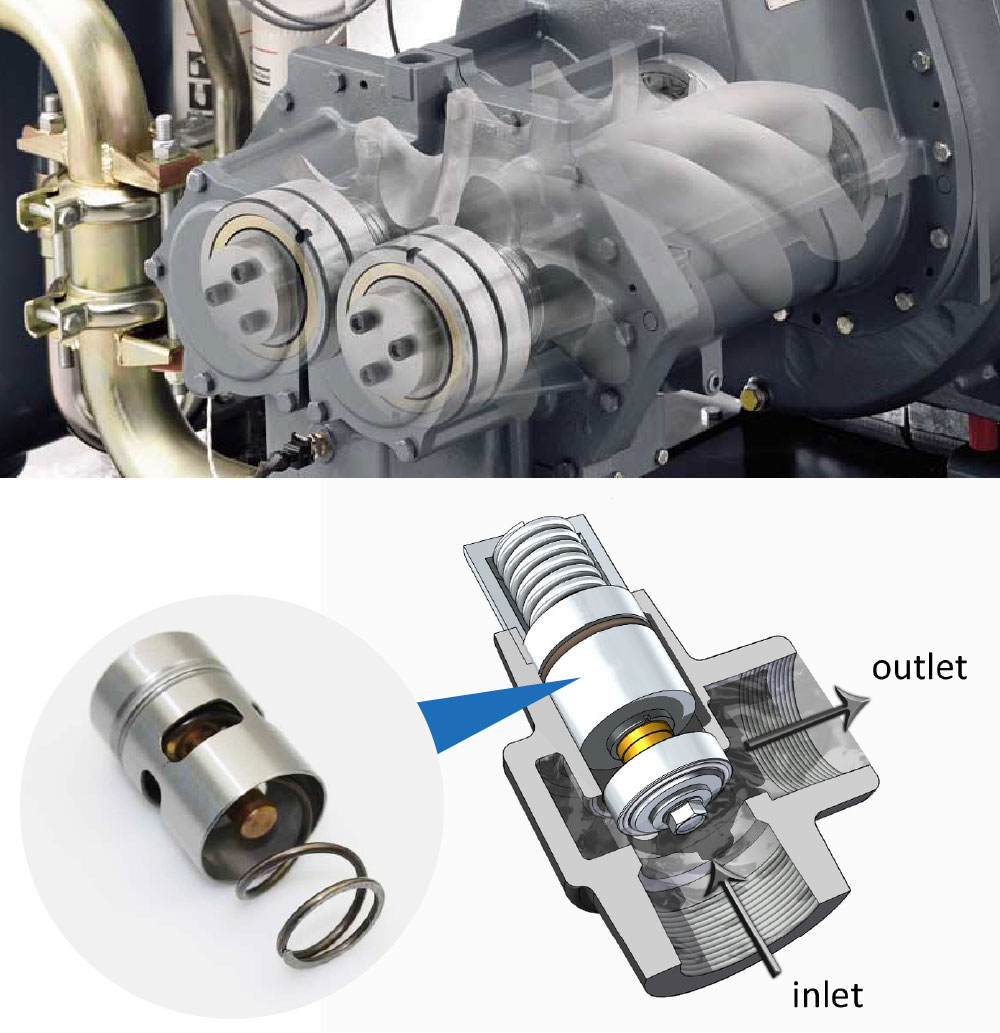

These modules can be combined and configured according to certain rules. The application of programmable logic controller in mechanical and electrical control of mine is mainly composed of combined controllers. The working principle of programmable logic controller is to control the internal inorganic electric shock semiconductor circuit through the instructions issued by the control system, and operate according to the specified cycle operation system. This method only needs a few subtle time to process single instruction, several times faster than the traditional relay in the processing speed of the instruction. In the process of using traditional relays, thermostatic element unstable jitter of contact points often occurs, and the monitoring of the system’s program operation has no good diagnostic ability.

When the system has problems, it can not respond in time, which can easily lead to problems, but the loss caused by improper maintenance, but the programmable logic controller can solve these problems well. Programmable Logic Controller (PLC) is widely used in mechanical and electrical control of mines. The first is its flexible structure. The structural flexibility of PLC can make it large or small and can be applied in various occasions. Secondly, the operation is simple, the operation of programmable logic controller is relatively simple, for most workers in coal mine workshop, it is relatively easy to accept. The programming language of programmable logic controller is relatively simple, especially the graphical symbols of ladder diagram language are quite close to the relay circuit diagram in the actual operation.

Thirdly, it is another characteristic of the programmable logic controller, because it can be widely applied to all kinds of operations, so its existence can be seen in both coal mining and coal exploration. The programmable logic controller is mainly composed of power supply, central processing unit, memory, input and output interface circuit, chassis or rack, programmer, module and man-machine interface. Now we mainly introduce the CPU and the programmer. The central processor is the control center and core of the programmable logic controller. Without the central processor, there would be no programmable logic controller. Each programmable logic controller has at least one CPU and two or more controllers individually. The programmer is an indispensable device for the development and application of programmable logic controller and the detection and operation. Especially in the mine work, the pre-exploration, meal and other work of the coal mine need the programmer to do a good job of preparation. PLC is an electronic system of digital operation, which is designed for application in industrial environment. It uses programmable memory to store instructions for logic operation, sequence control, timing, counting and arithmetic operation, and through digital and analog input and output. Control various types of machinery or production processes. PLC and its related equipment are designed according to the principle of easy integration with industrial controller system and easy expansion of functions. The state of mine electromechanical control operation can directly affect the working process of the whole mine, so a reasonable logic controller is needed to complete the control of the state of mine electromechanical operation. Programmable logic controller is a very important means, its role is mainly manifested in the following aspects. The application of programmable logic controller improves work efficiency effectively. Exploration and mining work in mining area are heavy-duty work, so the application of programmable logic controller replaces the application of traditional large-scale relays and improves work efficiency to a certain extent. In the electromechanical Department of coal mine, report configuration is very important.

Programmable Logic Controller (PLC) is a report editor that automatically generates messages, operations, archives and current or archived data.

Compared with the traditional human work industry, not only the work efficiency is greatly improved, but also the accuracy and precision are greatly improved, which is conducive to the further development of coal mine work. The application of programmable logic controller effectively guarantees the safety of mechanical and electrical control in coal mine. The alarm record settings in the programmable logic controller provide display and operation options to obtain and archive the results. It can arbitrarily select message speed, message level, message type, message display and report forms. At the same time, the level of programmable logic controller in dealing with analog capacity, digital computing capacity, man-machine interface capacity and network capacity has been gradually improved, which plays an important role in maintaining the safety of enterprises, especially mining areas. The application of programmable logic controller effectively promotes the continuous innovation of relay. With the gradual improvement of science and technology level in the development of coal mines in China, more and more objective requirements need to be solved by science and technology, which to a certain extent promotes the continuous innovation of programmable logic controller. As early as the end of the 20th century, the programmable logic controller was divided into one bit and four bits according to the characters of the CPU. Today, it has been expanded from the original one bit and four bits to eight bits, 16 bits, 32 bits and 64 bits. Not only its workload has been further increased, but also its accuracy has been greatly improved. This is mainly due to the demand of practical work, which promotes the development and innovation of programmable logic controller, and for the development of large-scale coal mines, these technological innovations also help to improve the mechanical and electrical control in coal mine work. At present, the application of PLC system in mechanical and electrical control in mining area is very extensive.

It can not only guarantee the normal and stable operation of mechanical and electrical system in mining area, but also simplify the operation procedure, further improve the efficiency of mechanical and electrical operation in mining area, and create greater social and economic benefits for mining enterprises. According to the practice of mining production, the development prospects of PLC will be better in the future, except for its development direction. In order to improve the operation accuracy of the system processor, the man-machine interface should be designed to control the mechanical and electrical operation of the mining area by using the man-machine interface, so as to effectively improve the production capacity of the mining area.

With the continuous development of science and technology in our country, the application level of programmable logic controller (PLC) technology is getting higher and higher, and its accuracy is increasing gradually. Its structure flexibility and operation convenience can largely meet the requirements of modern mine electromechanical control, so its application scope in mine electromechanical control is more and more extensive.