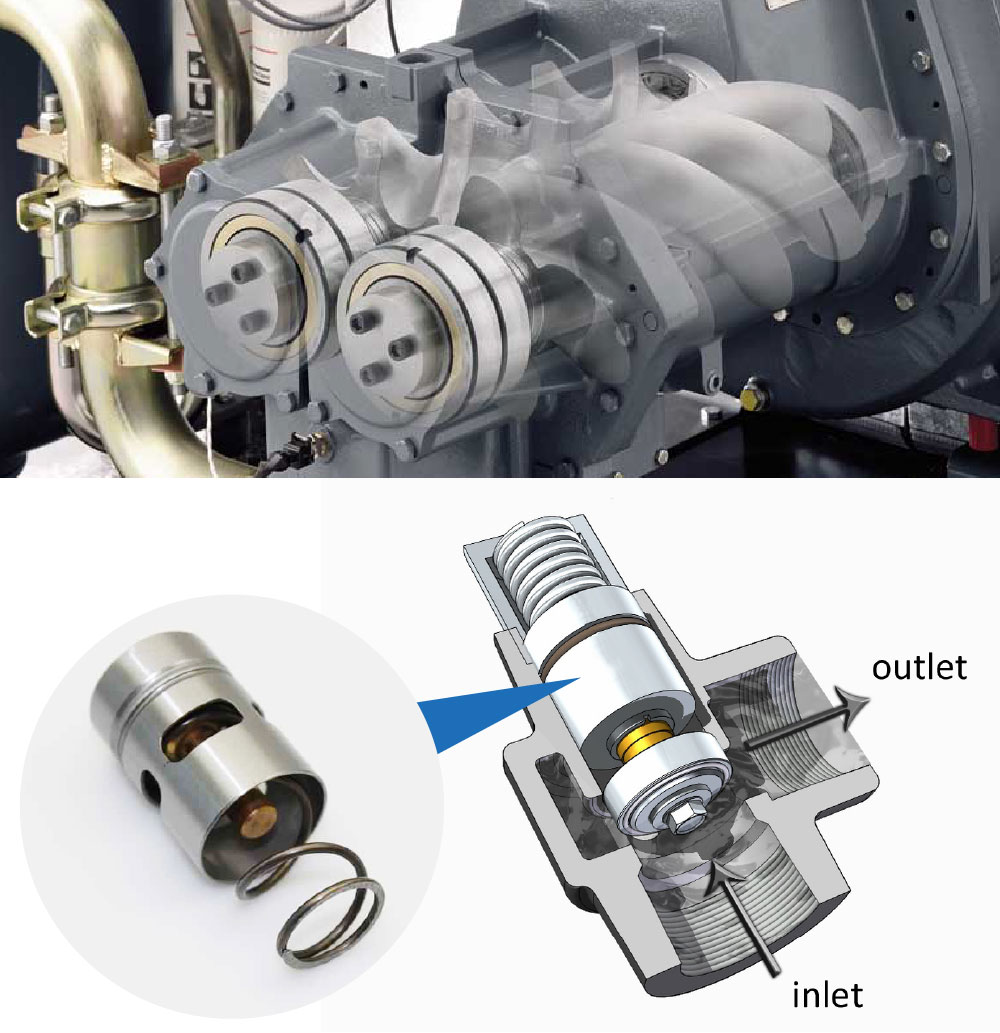

This paper introduces the localization research, development and manufacture of MPC box on the main engine of intelligent diesel engine (ME diesel engine). Some functions of imported equipment are improved, explored and innovated. Because the electrical parts of ME-type main engine are mostly imported parts, their foreign ordering costs are high, the ordering cycle is long, and they are subject to the restriction of others, so diesel engine manufacturers need to improve the localization rate of diesel engine electrical parts and components, so as to reduce costs and increase efficiency, in order to meet the increasing demand of marine products for the performance of main engine and enhance the international shipping market. Field competitiveness. The MPC multi-function control system of ME diesel engine is realized by centralizing the multi-Purpose Controller (MPC) multi-function control module in the cabinet, which consists of (Fig. 1): the main engine interface control unit (EICU), which mainly acts as an interface controller, and the main engine control unit (ECU), thermostatic element which integrates part of the remote control system and speed regulation of the traditional diesel engine. The functions of the controller; the cylinder control unit (CCU) controls the fuel injection, exhaust, cylinder fuel injection and starting air of each cylinder; the auxiliary control unit (ACU) controls some auxiliary equipment of the main engine, such as blower, HPS electric pump, etc; and a set of multi-functional control system is composed with other control units. There are three kinds of MPC control boxes according to the form of box: MPC control boxes without ECP junction boxes, MPC control boxes with ECP junction boxes and MPC control boxes with ECC junction boxes. The main components of MPC control box are the box body, module and the bracket for the installation of the box body. By sorting out and digesting the manufacturing technology and technological requirements of the imported box body, we trial-produce the MPC box body and purchase the electronic module, and complete the installation, wiring and debugging of the whole set of MPC control box, and meet the requirements of IEC 61000-4-2 and IEC 61000-2. – 4-3 EMC requirements.

So as to meet the needs of partial localization of MPC control box. MPC control box includes ACU control box, ECU control box, CCU control box, EICU control box, etc. Because the main components installed in these boxes are multi-functional controller module, for this more precise module, the requirements of environment and box are relatively high, therefore, the requirements of MPC control box for EMC (electromagnetic interference), that is, for the box body. The shielding requirement is very high, which is also the difficulty of this tackle. It’s a difficult start for everything. We have made many market research, and after collecting and testing the domestic magnetic strips and improving the manufacturing process of the box, we sent the sample to Jiangsu Institute of Electronic Information Product Quality Supervision and Inspection (Wuxi) for electromagnetic compatibility (ESD immunity test, radio frequency electromagnetic field radiation). Radiation immunity test) type approval test and successful certification, which is a crucial affirmation of our products. The control box type of the MPC board includes not only the above boxes, but also some wiring boxes, such as PDB wiring boxes, ECS wiring boxes, MOP wiring boxes, TSA wiring boxes, etc. The components installed in these boxes are wiring terminals, so the electromagnetic compatibility of the boxes is not high, but the protection level of the boxes is relatively high. According to our digestion of imported casting technology, and on the premise of meeting its protection level, through technical improvement and process optimization, we changed the casting into sheet metal parts, and manufactured samples of PDB box and ECS box, and sent the samples to 704 institutes for protection level test, and successfully obtained IP66 protection level certificate. This is an affirmation for the box made by us. More importantly, after mass production in the future, the cost savings are particularly considerable, which has a good effect on reducing cost and gaining for the whole enterprise. The new generation of MPC control box is named ECC control box. This type of MPC control box concentrates modules in two large boxes. In addition, the wiring technology of ECC control box has been upgraded, the requirements of cable laying and the processing of shielding layer flanging are special.

Although this type of control box has many advantages, it also has disadvantages when it has great advantages. Because of the existence of some unfavorable factors, such as the larger size of the box, the centralized modules and the installation environment, it is a very serious test whether our box can work normally in the environment of severe vibration without the damage of the box. Therefore, based on this point, we send the samples we made to the test station for vibration type test and pass through them. Our unremitting efforts, in the very strict requirements of the test standards, successfully passed the test, and successfully obtained the type test certificate. MPC control box is the core of the electronic control system of M E diesel engine.

The main engine control unit (E C U), main engine interface control unit (EICU), auxiliary unit (ACU) and cylinder control unit (CCU) are all completed by the same multi-function control module (MPC).

The multi-function control module integrates the hardware resources of all the control units, and only needs to pass through the non-MPC module. The same software realizes different control unit functions. This design idea is helpful to the standardization, modularization and reliability requirements of the electronic control system. If one of them fails, it can be replaced by other units (by modifying the software or hardware jumper), which greatly increases the reliability and versatility of the electronic control system.

The manufacturing process of MPC control box is different from that of conventional junction box. This kind of box has high requirements for electromagnetic compatibility and shielding. Therefore, 2 mm galvanized sheet metal is used as raw material for ACU (ECU, CCU, EICU, etc.) control box. In order to make the inner conductivity of the box better, it is required to paint only the outer part of the box without painting inside. In addition, the most critical point is that we adopt the way of placing conductive foam cotton on the inside of the panel to enhance the shielding and anti-interference ability of the box, so as to meet the requirements of EMC test.

In addition, the cable laying and wiring technology of MPC control box is also quite special. Firstly, when the filler box enters the ACU (ECU, CCU, EICU, etc.) MPC control box, the locking nut and inner core of the filler box are inserted into the cable, and the cable shielding layer 360 degrees are evenly turned over on the inner core sleeve, and the inner core of the filler letter is covered with the inner core. Shielding wire is inserted into the stuffing box body, and then the nut is locked so that the cable shielding layer is pressed on the stuffing box body and the inner core sleeve, thus ensuring the good grounding of the cable shielding layer. This process is a very critical step, not only to play a good grounding effect, but also to achieve flanging beautiful, burr-free.

Secondly, for the type of ECC control box, because of the centralized layout of modules, the connection between modules and modules is completed in the inner part of the box without the filler box. Therefore, a shielding row is installed next to each module of the box. When the shielding layer of the cable is flanged 360 degrees and processed, it is bound to each corresponding one. The shielding row ensures good grounding of cable shielding layer. The debugging of the whole set of MPC control box equipment needs to be completed by two MOP hosts. Similar to conventional electrical equipment, MPC control box needs to check the positive and negative DC power supply of DC24V, insulation, connection and so on.

Another special check is to check the network connectivity of each module with the help of MOP host. Whether the state is good or not, in the case of good network state, upload data parameters, and use software to complete various tasks of diesel engine control, monitoring, fault diagnosis and so on. The anti-interference and electromagnetic compatibility characteristics of MPC control box; the improvement of manufacturing and wiring technology of MPC control box; the serialization of MPC control box, which can be applied to diesel engines of various ME models; the design of practical new bracket, which is convenient for installation, wiring, debugging and transportation of control box. As ME-type main engine is the future development trend, and MPC control box is the core of the electronic control system, MPC control box has been widely used in various types of diesel engines. The products are approved by owners and shipowners, and are comparable to imported equipment in terms of manufacturing technology and construction technology.