Air conditioning system is a very important part of the vehicle, it can measure the specific comfort level of the vehicle.

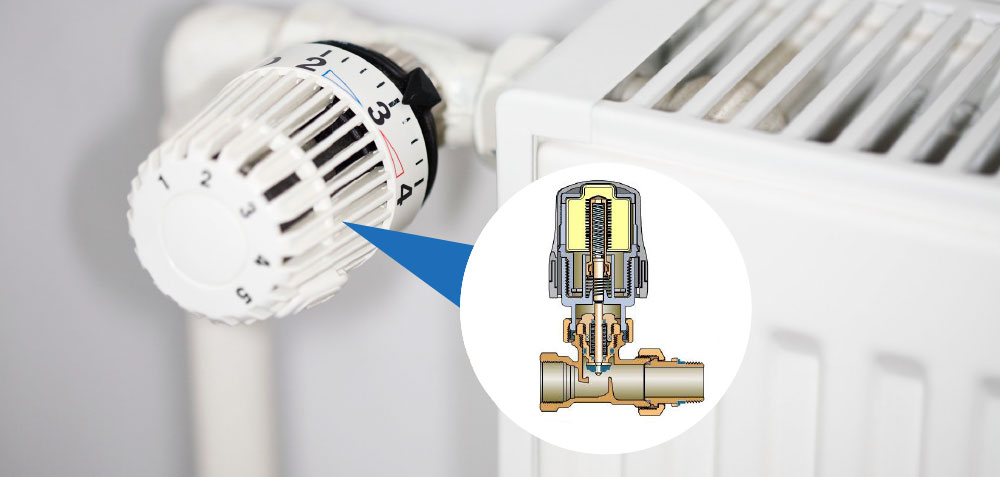

Consumers have a high demand for vehicle comfort, which poses a major challenge to the research and development of vehicle functions. Therefore, people began to study the operational performance, logical operation and efficiency of air conditioning system. This paper briefly describes the actual working principle of air conditioning system and the principle of automated testing, and then explores the realization of automated testing. When developing air conditioning controllers, we can test the products in an automated way, which will save the time spent in validating the software. The time saved is spent on the calibration of air-conditioning heating and cooling problems, thus making the vehicle more comfortable. At the same time, it can also provide more time for automated testing to improve the quality of testing and reduce the cost of investment. In this regard, the author discusses the automatic test of air conditioning controller. Air conditioning system can play the role of refrigeration and dehumidification in vehicles. In the automatic mode, the air conditioning controller can automatically control the motor position and air volume of the air door according to the temperature difference between the inside and outside of the car, so that the humidity and temperature in the car can make people feel comfortable. For example: single-zone air conditioning system. The parts of the system include internal circulation air door motor, blow-foot air door motor, refrigeratory, evaporator, condenser, pressure sensor, motor position sensor, blow-window air door motor, blower, temperature sensor and evaporator.

In theory, any test can be automated, but in fact, only part of the test needs to be applied to automated test. Generally, the automatic test can be selected according to the following conditions: the order of execution is the same, but the data should be different, and test errors are easy to occur; a large number of variables need to be input into the test; special equipment needs to be used to input the device for testing, while activating the system, analysis and research output.

The key points of selecting appropriate automation test are as follows: the successful test can be tested in unattended condition, thus increasing the available time. And those tedious test activities can be completed by test automation. If people test, many kinds of errors will easily occur.

Therefore, thermostatic element reasonable application automation can effectively improve the quality of test. Building a sound regression test suite enables testers to apply their time to new functional testing and modifications. Automated testing ensures that a test is always carried out and executed accurately. At the same time, it can test the difference between the expected output and the actual output. In automated testing, we must build a perfect hardware model. In the process of designing the hardware of the system model, reasonable application of the following components can successfully complete the test of vehicle controller: PXI system such as acquisition board, input signal, signal conditioning board, output signal, communication board, analog output signal board and analog input signal board; power control; electronic load. BOB box with conditioning performance; air conditioning controller; industrial computer; programmable power supply [2]. The actual working principle is that the input system and output system are controlled, judged and detected by LabVIEW software. PXI system can be controlled by labview, so that hardware can collect, input and output in the loop system. Power control belongs to the power supply system in the system, and programmable power supply can be used to control the voltage in the controller during testing. The application of BOB can adjust and detect the input and output signals, and keep the input and output true. Before programmed processing of test cases, the interface responsible for control should be developed in LabVIEW software system, and the flow of automatic testing should be built in TestStand. While taking the test cases as the basis, the specific requirements of the test should be analyzed and sorted out. Through detailed analysis of the specific technical parameters of the test case, the LabVIEW system is developed. The test script is written by the editor in the LabVIEW system, and then the test system debugs the column script, which makes the test document complete automatically.

Realize automatic testing: Change some functional requirements existing in the test file into corresponding software devices, and then realize functional control, and then test the system for debugging and operation. Through meticulous processing of the tested object, judging, analyzing and collecting the output results from the tested object, and then automatically testing the functions of the air conditioning controller. The actual implementation is as follows: the LabVIEW software calls the technical parameters in the test case, and then applies the hardware and software models in the test system to make the PXI system simulate the number of input numbers and drive the number of input numbers. When all the analog signals output by Labview enter the air conditioning controller, the air conditioning controller will use its own functions to identify the analog signals logically, and then control the load motor such as blower and wind door motor for output processing. The digital output by air conditioning controller will be centralized processed and collected when it passes through DAQ card, and then the processed signal will be fed back to labview. Finally, the actual input and output of air conditioning will be displayed on the interface of labview, so that the tester can easily read the input and output data of the system and master them. Input and output [4]. Because the relationship between input and output is not set in the test case, it is necessary to compare the set output and the actual output strictly, and judge whether the test structure and the expected settings are in conformity. If the settings are in conformity with the actual settings, then we can consider that the test is successful.

If the actual output is not in conformity with the set output, Then we decide that the test is unsuccessful and we should retest it. In a word, testing products are the main link of pushing products into the market.

By building test models and compiling test execution procedures, automatic testing of air conditioning functions not only saves investment costs and development time, but also ensures the consistency and accuracy of products, thereby improving the comfort of vehicles and the market of products. Field competitiveness.