This paper presents a boiler water level controller based on VHDL language and field programmable gate array (FPGA).

It not only has stable performance, strong anti-jamming ability, less hardware resources, simple structure, but also can configure system parameters online. It can guarantee the normal operation of the system, and is conducive to the upgrading of device performance.

Pragmatic value.

Boiler water level control accuracy has different requirements for the accuracy of the controller. Boiler water level detectors and simple limit controllers with no accuracy requirements are all right. Boilers with high control accuracy requirements need high precision control. There are many kinds of controllers. Single-chip computer is a common control mode, but the single-chip computer system is more complex and anti-interference performance is not easy to improve. It can also be controlled by general single-loop regulator PLC, but the performance-price ratio is not high. The system uses an on-line programmable controller with FPGA chip, which not only has stable performance and strong anti-interference ability, but also can configure system parameters online, and can ensure the normal operation of the system.

The hardware of the system controller is designed by VHDL language for debugging, maintenance and system upgrade. The control algorithm of the system adopts PID control algorithm to improve the accuracy of the controller.

The water level detection component is mainly composed of a liquid level sensor, which is used to measure the liquid level in a boiler and convert the liquid level signal into a voltage signal output. Signal amplifier unit, because the output voltage signal intensity of liquid level measuring device is weak, must amplify the signal before long-distance transmission.

The signal amplifier unit amplifies it and transmits the signal to the controller controller in the control room far away from the boiler room. The control and regulation unit is mainly composed of a controller, which is responsible for collecting, storing and calculating all kinds of control signals in the system and outputting the processed information outward to control the water level in the boiler. Man-machine interaction component, the system is equipped with operator’s operation switch, which can not only run normally through the manual control system of the operating table when the system fails, but also debug the system on-line artificially when the system runs normally. Drive the actuator.

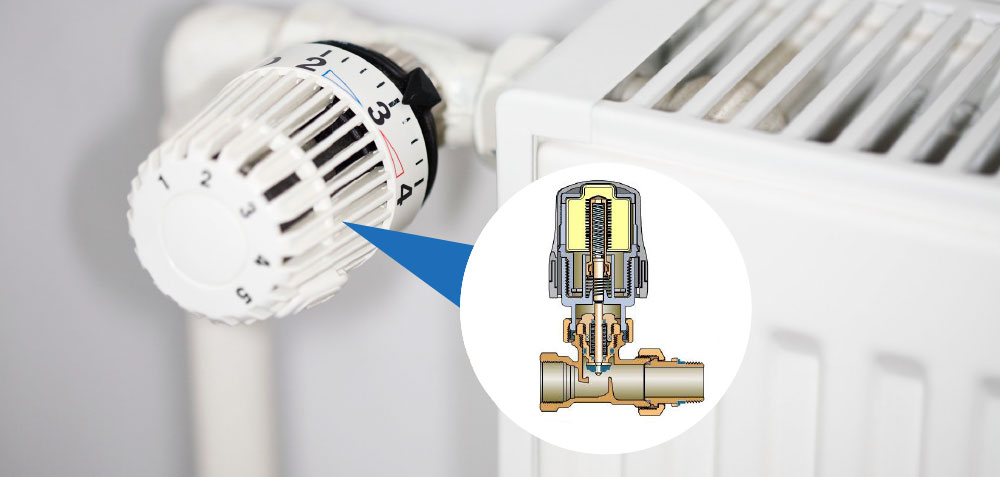

Because the intensity of the control signal output by the controller can not directly drive the executive components, the power amplifier is mainly composed of thyristor circuit. The actuating part is composed of an electronic control valve, which can control the water intake of the boiler to regulate the water level by controlling the opening of the valve. The system uses the FPGA as the control unit to control the water level in the boiler, which has high control degree, low cost and high control efficiency, thermostatic element and can meet the control requirements of most boilers. In practical application, the bigger the volume of the boiler is, the greater the consistency of the control parameters will be. Simple PID control may be difficult to meet the accuracy requirements.

If the overshoot is too large, the system can adjust and add other control algorithms online according to the actual field.

The system can easily and quickly adjust the control parameters to meet the accuracy requirements.