PLC programmable controller is the mainstream of the development and application of electrical automation. Taking this as an example, this paper connects the adjustable water resistance step-down elements in series with the star-limited starting current of high voltage and large capacity three-phase asynchronous motor to realize smooth starting of motor. This paper also introduces the advanced small three-phase variable frequency speed servo motor drive pole plate rise and fall, adjust the size of water resistance value, so as to start smoothly and slowly. Three-phase AC cage asynchronous motors with high voltage and large capacity of 0.4-10 kV and 75-104kW are difficult to start. PLC programmable controller with soft starting of lower series water resistance is used to control them.

It is suitable for large-scale production machinery in building materials, metallurgy, mining, petrochemical and water conservancy industries, such as ball mill, rolling mill, crusher, hoist and fan. Pumps, etc. The soft startup of lower series water resistance with ideal starting effect and smooth stepless regulation is obtained.

Asynchronous motor starting can be divided into direct starting, step-down starting and frequency conversion starting. Full voltage direct starting is only suitable for small asynchronous motors; frequency sensitive rheostat is only suitable for winding motors, and winding motors are expensive and limited in application; reactor and autotransformer step-down starting is the most common starting mode for large and medium cage asynchronous motors at present, and the starting current is still as high as 3-5 IN. The impact of power grid and equipment is still large, and the failure of start-up causes damage to start-up equipment from time to time. Frequency conversion speed regulating start-up, although it has little impact on power grid and equipment, has good effect and is widely used, but high-power frequency converter speed governor is expensive and low cost-effective, so it is generally not used. The soft start of water resistance step-down can control the starting current Ist within 1.3-3IN to realize soft start and continuous start, so that the output end of the high voltage motor shaft can obtain a relatively soft mechanical characteristics. The main part of the water resistance starting cabinet is the water resistance cabinet, which conducts electricity by electrolyte ions dissolved in water. The electrolyte is filled between two planar plates (i.e. the two electrodes of water resistance) to form an ionic conductor, which limits the starting current Ist of the motor and smoothly adjusts its voltage drop, so that the motor can obtain a steady rising terminal voltage and reduce the pair of pairs. Impact of power grid.

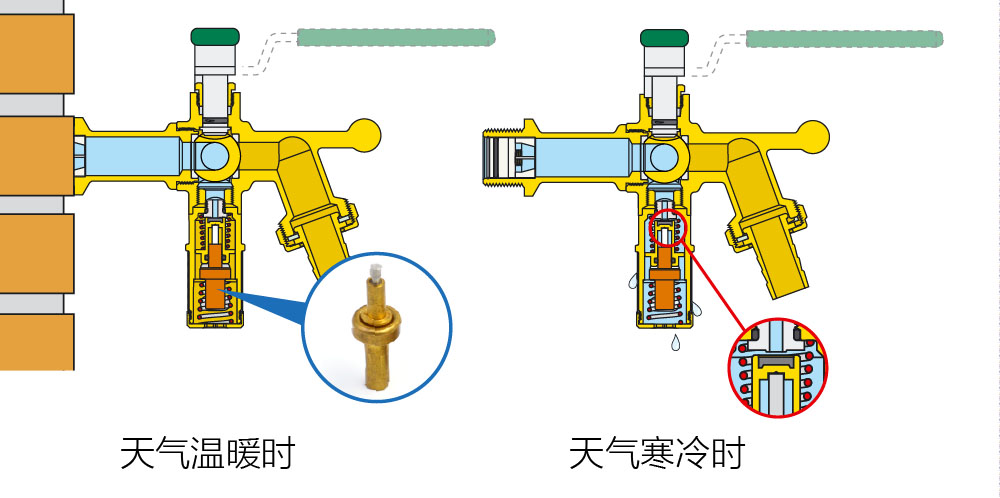

Because there is no inductive starting element, the water resistance flowing through Ist consumes active power, but the power factor of starting is smaller than the step-down starting of reactor and autotransformer. Usually also called soft resistance cabinet, liquid resistance cabinet, also referred to as water resistance cabinet. The resistance value of water resistance is achieved by changing the concentration of conductive medium in the water resistance box and the distance between the two plates (which is adjusted with the starting current). In the field, it can be adjusted according to the actual parameters of the motor. During the starting process, the initial resistance gradually changes with the decreasing of the starting current. It is close to 0_, and the starting is stable. Secondary switching impact, adjustable and easy to use. The water resistance starting cabinet is mainly suitable for starting three-phase large squirrel cage asynchronous motors with rated voltage of 0.4-10 kV and power of 75-10 Mw at AC50 and 60 Hz. Its structure mainly consists of frame, electrode plate moving lifting system, resistance liquid box, high-voltage vacuum circuit breaker and electrical control system. The movable plate moves up and down through the connection of insulator and movable seat, and the fixed plate is installed at the bottom of the resistance liquid box.

The three resistance liquid tanks are made of insulating materials and are mounted on the frame. The electrical part is installed in the distribution box on the upper left of phase A liquid resistance box, as shown in Figure 1.

The vacuum circuit breaker, high voltage detection, relay protection, interlock and other circuit elements of the motor are installed in the running cabinet, and the star short-sealing circuit breaker is installed in the star starting cabinet. Each circuit breaker has switching and interlocking circuits, such as closing and interlocking circuits, closing energy storage motors and linkage mechanical action interlocking. The lower series resistance is used to short seal the star points of high-voltage and large-capacity asynchronous motors, which reduces the potential between the three water resistance tanks and improves the safety factor of water resistance.

This part belongs to high-voltage electrical appliances, and there are many protective interlocking circuits. Because of the space limitation, it only gives a rough hint and does not make a detailed analysis, focusing on the description of the application part of FX2N series PLC control. Because there are many auxiliary equipments in the high-voltage system, the layout is dispersed, the interlocking is high and the circuit is complex, the working principle of series resistance starting under the high-voltage motor is explained in detail step by step.

Hydroelectric cabinet detects the conditions that permit motor starting: Star point cabinet QF2 is in the open state, liquid temperature is between – 10 ~85 ~C, thermostatic element operation cabinet QF1 is open, ST2 is closed, liquid level is normal SQ3 is closed, then PLC Y30 is connected to KA1, signal to operation cabinet can start high voltage motor starting instruction, operation cabinet can close QF1 through energy storage starting and closing. Start signal finish the task. In the starting process, if the main motor QF1 is closed 50 seconds later, the star QF2 has not been short-sealed, the main motor has been running under low voltage, at this time the liquid temperature may rise to 85 C, the PLC detects the accident status, Y35 is connected to KA5, closes the QF1 switch circuit, disconnects the main motor power supply, so as to avoid the primary current boiling water in the resistance box, and protects the water resistance cabinet and the main motor. Motor, moving plate stay in the middle position, that is, starting failure.

At the same time, the alarm should be prompted. If the main motor operates for a long time, the water resistance cabinet is always in the normal or low temperature state, the internal liquid diffuse volatilization will also be reduced. When the liquid temperature is below – 10 C or the liquid level is below the detection line, the PLC will also detect the accident state and give an alarm, but it will not trip and stop, only affect the next start.

Whether the main motor is running normally or starting normally, as long as any stop button is pressed beside the motor, such as the operating table, the operating cabinet, the star cabinet and the water resistance cabinet, the QF1 and QF2 can be switched off. However, the shutdown caused by misoperation at any place will have an impact on the whole process, and there is no alarm prompt. With the rapid development of sensor and detection technology, the application of PLC and variable frequency speed regulation in water resistance starting ensures its safety, improves its reliability, and reduces its cost significantly compared with other starters, thus becoming the first choice for starting high-power and high-voltage asynchronous motors.