With the wide application of PLC in industrial production, the improvement of PLC control function makes the application software of predictive controller, fuzzy controller and other strong functions come into being.

This paper briefly introduces the research and implementation of PLC fuzzy controller, and expounds the algorithm and system of PLC fuzzy controller, and the design steps of the controller, in order to verify the reliability and effectiveness of the PLC fuzzy controller. Fuzzy control embedded in PLC is called Fuzzy Controller, which is composed of Fuzzy Special Chip. FZ001 of Omron Company, Modicon A120 and A250 of AEG Company of Germany have standard Fuzzy Control Software Package. At present, Fuzzy Special Module has been developed and manufactured by many PLC manufacturers, which is one of the most widely used occasions. Controller.

Fuzzy controller is the most mature branch of current intelligent control technology. Because it integrates with conventional control, it has the characteristics of fast reasoning speed, good adaptability, strong system stability and high control precision. It can solve complex control problems, and is suitable for non-professional technicians to control, and can save system parameters in operation.

Number regulation process, therefore very suitable for industrial production operations, plays a very important role in transforming productivity and accelerating the wide application of control technology. PLC fuzzy control system links the two ends through input interface and output interface. The important part in the middle is composed of detection device, controlled object and actuator. Fuzzy controller plays the roles of calculating control variables, fuzzy quantification processing and fuzzy control rules. From the graph, we can see clearly that the core of the whole system is composed of fuzzy controllers. Only the improvement of the performance of the fuzzy controllers can drive the optimal operation of the whole system. Functionally, fuzzy interface, knowledge base, fuzzy inference engine and de-fuzzification structure constitute the fuzzy controller. Fuzzy interface plays the role of transforming the precise quantity into the fuzzy quantity; the knowledge base contains the control target of the knowledge and requirement in the application field; the design idea of the fuzzy reasoning is based on the thinking mode of human beings; the function of the clear interface here is to change the fuzzy quantity into the clear quantity in order to meet the operation needs of the system.

。 According to the number of independent input variables and output variables, we divide the fuzzy control system into two types of control systems, namely single variable and multi-variable. In the whole process of fuzzy control operation, the fuzzy control algorithm is composed of fuzzification, fuzzy reasoning and clarification. Firstly, the input quantity is transformed into the quantity of the fuzzy control requirement, so that these quantities can be transported to the field of the system requirement. The quantities of these systems are then fuzzily processed and expressed as fuzzy sets.

The whole operation process is called fuzzification operation. The fuzzy controller carries out the technology in the knowledge base according to the control objective set by itself.

Transformations include the fuzzy partition of membership functions, input and output scales, and spatial factors of various linguistic variables; the fuzzy inference engine simulates reasoning according to human’s fuzzy concepts and transforms the fuzzy “IFTHEN” in the rule base into a mapping according to the rules of fuzzy logic; the reasoned fuzzy variables can not be used for direct control. Like, it needs to be translated into a precise quantity to control the actuator. This process is called clarification. In order to achieve a certain goal of programming, and according to the actual control problems to design a certain process of controled controller is called a general fuzzy controller, which according to the different needs of customers programming, flexible operation of the workflow.

The greatest difference of the commonly used fuzzy controllers lies in their generalization, which abandons the goal of high control accuracy. In order to achieve this characteristic, the fuzzy controllers use the methods of PLC on-line table lookup and computer off-line calculation to realize the fuzzy control.

The specific process is: the computer off-line in order to get the total control table of the fuzzy controller, the process of fuzzy reasoning is simplified and fuzzified, and after necessary debugging and modification of the program, these processes are stored in the memory of the PLC system in the form of data modules, and finally managed by a subroutine inquiring the table. The operation process of the general fuzzy controller described above is precisely because the two-dimensional fuzzy controller can reflect the action characteristics of the input variables in the controlled process more strictly, and has good generality, and is better than the control effect of the one-dimensional fuzzy controller.

It is simpler than the three-dimensional fuzzy controller in calculation. Therefore, the two-dimensional fuzzy controller is applied to industrial students. In production, two-dimensional fuzzy controller is widely used as a fuzzy control system. In the control design of the fuzzy controller based on PLC, besides the structure of the controller, it also involves the off-line design part of the fuzzy controller, ETEP7 to realize the design of the fuzzy controller, and the simulation and verification of the fuzzy controller of the PLC.

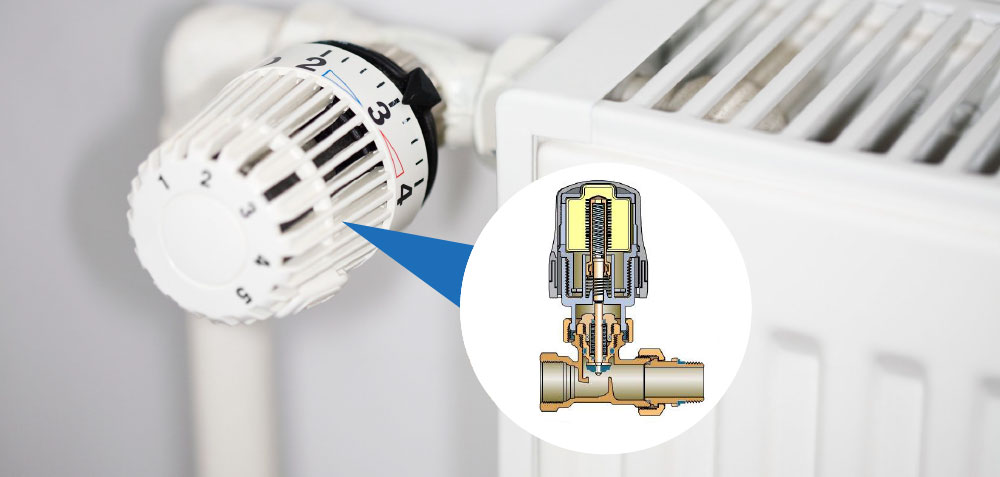

The off-line design part of the fuzzy controller generally includes the specific algorithm design and the design of the fuzzy logic toolbox based on MATLAB; ETEP7 implements the design of the fuzzy controller including the function blocks of the fuzzy algorithm and the fuzzy algorithm; and the simulation verification of the fuzzy controller of the PLC includes the establishment of the simulation system and the verification of the simulation results. In summary, no matter how complex the operation process of the PLC fuzzy controller is, it is completed by off-line calculation of the computer, and the data obtained can be invoked by the PLC on-line. After adopting MTALAB off-line design and PLC on-line table lookup method, the fuzzy controller based on PLC simplifies the complicated and tedious work, thermostatic element which is not only convenient for users, but also improves the real-time control for industrial production.

In the future, the improvement of PLC fuzzy controller can be further explored in algorithm and control effect, and further research on the development of PLC fuzzy PID controller.