Aiming at the problem of non-linear modeling of electro-hydraulic position servo system of valve-controlled cylinder, a neural network is used to identify the system model. LM genetic algorithm is used to modify the weights and thresholds of the three-layer BP neural network, and the input/output data of the training system is used to establish the identification model of the non-linear system.

Based on this model, a fuzzy PI controller is designed to automatically adjust and modify the rules of the fuzzy controller online by using the intelligent weight function. Using xPC technology, a valve-controlled cylinder servo test-bed is built. The step output signal of the test-bed is used as the improved BP neural network identification signal, and the sinusoidal output signal of the test-bed is used as the verification signal.

Experiments show that the credibility of the neural network identification model is verified, and the control effect of the former is better by comparing the experimental curves of the intelligent weight function fuzzy PI controller and the fuzzy controller. Establishing the mathematical model of the system is the basis of the control theory. The electro-hydraulic servo system is a non-linear system with uncertain model parameters and structure because of the dead-time characteristics, gain and self-excited oscillation of the system. Therefore, a mathematical model equivalent to the actual system is obtained in engineering application and controlled on this basis. The simulation design of the device is very difficult. Neural network is widely used in many fields, but there are still some problems in the identification of nonlinear system model, such as slow convergence speed and long learning time. By analyzing the current situation and existing problems of standard BP algorithm [4-6], the identification model of electro-hydraulic position servo system of valve-controlled cylinder is established by combining BP neural network structure with genetic algorithm.

Fuzzy control can control the controlled object by making fuzzy rules based on experience, especially for the uncertain system with time-varying nonlinearity. However, once the correction factor alpha of the conventional fuzzy controller is determined, its fuzzy control rules can not be changed. The fuzzy controller with intelligent weight function can adjust the correction factor alpha online by the intelligent weight function to achieve the purpose of online self-adjusting the fuzzy control rules, so that the fuzzy controller can adapt to the changes of the controlled object [7-9]. Due to the lack of integral links, the problem of steady-state error is difficult to eliminate in the control process of the fuzzy controller.

In this paper, an intelligent weight function fuzzy PI controller is designed for improving and eliminating the steady-state error of the valve-controlled cylinder electro-hydraulic servo system and realizing on-line self-adjustment of the fuzzy rules. The identification model and model of the neural network are verified by means of the hardware-in-the-loop simulation environment of the xPC real-time system and the MATLAB software [10]. Effectiveness of Fuzzy Controller. The hardware-in-the-loop simulation environment of the electro-hydraulic servo experimental platform based on xPC technology is shown in Fig. 1. In the xPC Target environment, the host computer is a PC equipped with MATLAB/simulink software and the target computer is Yanhua Industrial Computer.

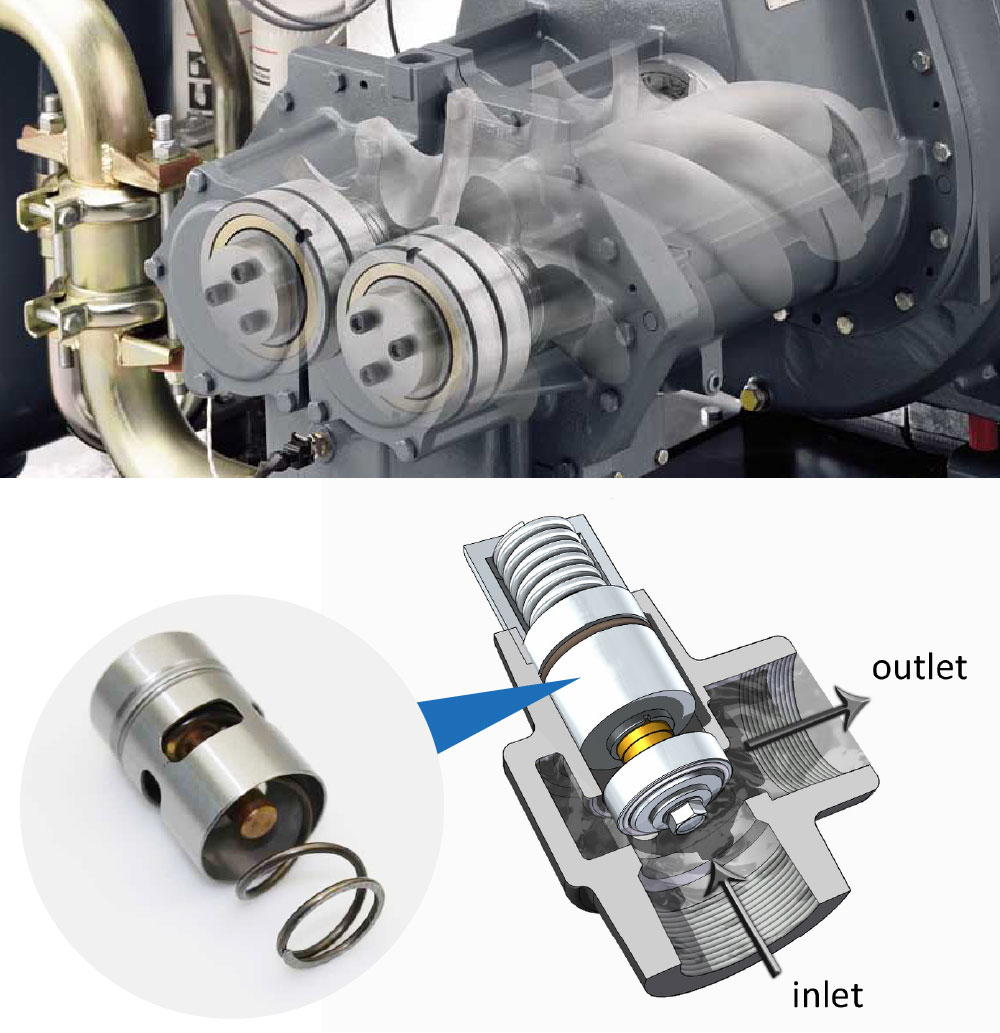

The two computers communicate through Ethernet LAN for real-time test of the controller and hardware-in-the-loop simulation of the system. The power mechanism of the test-bed is a typical symmetrical valve to control the symmetrical hydraulic cylinder model as shown in Figure 2. The computer provides the control signal Ur to the servo valve, and controls the hydraulic cylinder through the data output (D/A) card and servo amplifier. In order to realize closed-loop position control, the position signal U is fed back to the data acquisition card by the displacement sensor. The deviation value U is processed by the controller and amplified by the servo amplifier. Then the current signal is transmitted to the electro-hydraulic servo valve, so as to control the opening size of the servo valve and control the hydraulic pressure by controlling the flow change of the servo valve. The purpose of cylinder displacement is to display the real-time position of hydraulic cylinder on oscilloscope and display screen. BP algorithm of back propagation neural network determines weights by forward propagation of signals and back propagation of errors. In the forward propagation process, the input information is computed through the hidden layer and transmitted to the output layer. If the information from the output layer has errors with the expected output, the error signal propagates back along the original neural network path to correct the weights and thresholds of each layer of neurons, so that the square sum of the errors of the network decreases continuously.

This process is executed iteratively until the output of the output layer reaches the desired value or the set number of times of learning is reached and terminated. The convergence speed of standard BP algorithm is slow and the learning rate is not easy to determine, so it is difficult to be used in engineering practice. In order to optimize BP network, the commonly used optimization algorithms include variable rate algorithm, conjugate gradient algorithm, Gauss-Newton algorithm, LM algorithm, etc. [11-14]. Compared with other algorithms, LM algorithm not only has the local convergence of Gauss-Newton method, but also has the global characteristics of gradient descent method, which effectively improves the convergence performance of the network. When the actual output does not match the expected output, the error is expressed in E. EK (w) is the error. If wk denotes the vector consisting of the weight and threshold of the k th iteration, wk 1 denotes the vector consisting of the weight and threshold of the k th iteration. The relationship between wk 1 and wk is expressed as wk 1=wk w. LM algorithm is designed to avoid calculating Hessian matrix when it is modified at approximate second-order training rate.

The Jacobian matrix can be obtained by a standard feedforward network, so the LM algorithm is much faster than the gradient method. As can be seen from formula (2), if mu=0, it is Gauss-Newton method; if Mu is large, the LM algorithm approaches the gradient descent method. After each iteration, if the learning rate is reduced, when the expected output is close to the actual output, it is gradually similar to the Gauss-Newton method. This improves the learning rate. The application of neural network in system identification does not require pre-selection of the actual system model, but directly identifies the system through the input/output data of the training system. Because the neural network has the characteristics of non-linearity, it can not be restricted by the non-linear model. In this paper, a typical three-layer BP neural network is used, and then the weight and threshold of the neural network are modified by genetic algorithm to minimize the required error criterion function, so as to optimize the BP neural network, and finally establish the identification model, as shown in Figure 3. The position feedback closed-loop control is used to identify (electro-hydraulic position servo system). Considering the time-varying and disturbance of the nonlinear system, a series of experiments are carried out. The sinusoidal signal and step signal are used as input respectively to record the output data. In this way, in the hardware-in-the-loop simulation environment of xPC real-time system, the input and output data can be obtained online. The step signal data is used to improve the BP neural network system identification, and the sinusoidal signal is validated. In the MATLAB environment, input NNTool and enter the neural network toolbox to identify GUI. The training sample data is imported into GUI and the neural network is established. Using single input and single output electro-hydraulic servo system, the number of input nodes L=10 and the number of output nodes N=1 of the improved BP network are determined. For the selection of the number of hidden layer nodes, after repeated training, when M = 17, the error is the smallest and the accuracy is the highest. Transfer function types of each layer: unipolar S-type function is used in the hidden layer, linear transfer function purelin is used in the output layer, and LM (trainlm) algorithm is used in the learning algorithm. The mean square error (MSE) performance function network is used to correct the error function. Create a neural network as shown in Figure 4. The performance curve of LM algorithm (MSE) is shown in Fig. 5-7, with step signal as input. The training error parameters are set to 0001, and the rest are default values. The training error curve obtained achieves the set target value in the fourth step. The training output error curve is relatively smooth, indicating that the error is small. As can be seen from Figure 7, the correlation coefficient between the identification output and the actual output is above 09. According to the established identification model, any input of the nonlinear system can be identified and output.

It provides the precondition and guarantee for the further research on the control theory of this system. The two-dimensional fuzzy controller is commonly used in the fuzzy control. The query table of the fuzzy rules, the quantization factors Ke and Kc and the proportional factor Ku can not be changed in the control process once they are determined. Therefore, it is necessary to consider introducing correction factors of different sizes to realize self-adjustment of fuzzy control rules in different error E and EC levels. When the error E is large, the main task of control is to eliminate the error, and then the weight of error E in control rules should be larger. When the error E is small, the system is close to steady state, and the main task of control becomes to stabilize the system as soon as possible. In order to effectively reduce overshoot, the error in control rules should be changed. The weighted degree of EC is larger, so that the role of EC in error variation becomes larger. Common methods are [15]. The methods of introducing multiple adjustment factors, using self-adjustment factors and using self-adjustment functions are introduced. The intelligent weight function method used in this paper is a kind of self-adjusting function method. In the formula E and EC are the fuzzy values of error and error change respectively.

Obviously, the weight function of error alpha E and the weight function of error change alpha EC satisfy the condition of alpha e alpha ec=1. Intelligent weight function fuzzy control algorithm is a kind of human-like intelligent control strategy. Its characteristic is that the weight function is only a function of input variables.

Its control system can automatically adjust the weight function in real time according to the input variables, thus realizing on-line adjustment of the fuzzy control rules. In order to improve the control performance of the controller and eliminate the steady-state error, the PI control structure is introduced, as shown in Figure 8. Using the Fuzzy Inference System (FIS) editor in MATLAB, a two-dimensional fuzzy control system with two inputs (deviation E and deviation variation EC) and one output (control quantity U) is constructed. Mamdani reasoning method is adopted, in which the and algorithm of fuzzy logic adopts “prod”, or algorithm uses “probor”, clarification algorithm uses “centroid”, implication algorithm uses “prod” and synthesis algorithm uses “max”. The membership functions of fuzzy input variables (E and EC) and output variables (U) are all Gaussian membership functions. {Negative large, negative medium, negative small, negative, zero, positive, positive small, positive, positive large}={nb, nm, ns, n, z, thermostatic element p, ps, pm, pb}={6, 5, 4, 3, 2, 1, 0, 1, 2, 3, 4, 5, 6}. The membership functions of fuzzy subsets of input and output variables are shown in Table 1. The electro-hydraulic position servo system mainly controls the displacement of the piston of the hydraulic cylinder by controlling the opening size and speed of the valve of the electro-hydraulic servo valve. According to the knowledge and experience, nine fuzzy control rules can be summarized. The rules of fuzzy control are shown in Table 2. Based on the principle of intelligent weight function, the simulation diagram of intelligent weight function fuzzy PI control system is established under the environment of MATLAB/Simulink, as shown in Figure 9. In order to verify the effectiveness of intelligent weight function fuzzy PI controller based on neural network identification model in practical application, real-time control experiments were carried out on xPC hardware-in-the-loop simulation experimental platform. The experimental results of step response and sinusoidal response are shown in Fig. 11 and Fig. 12 respectively. Curve 1 is input, curve 2 is output of fuzzy control and curve 3 is output of intelligent weight function fuzzy PI controller. It can be seen from the graph that the steady-state performance and tracking performance of the fuzzy controller and the intelligent weight function fuzzy PI controller are good.

However, the step response curve has residual error because the integral term is not introduced into the fuzzy control, while the intelligent weight function fuzzy PI controller has almost no residual error, and the step response rises faster, the overshoot is smaller, and the tracking response time is shorter in the sinusoidal response. In this paper, taking the electro-hydraulic servo experimental platform as an example, the input and output data of the controlled object are obtained by XPC hardware-in-the-loop simulation sampling, and the neural network identification model based on LM algorithm is established by combining the structure of BP neural network with genetic algorithm. Experiments show that the intrinsic non-linear electro-hydraulic position servo system is identified by fitting the output of the external system of the neural network, and the neural network identification model obtained by adjusting the weights in the network has good reliability. Based on the model and the principle of intelligent weight function, a fuzzy PI controller with intelligent weight function is designed by using MATLAB/Simulink.