The so-called bidirectional DC-DC converter is a kind of converter which can transfer energy bidirectionally while maintaining the polarity of DC voltage unchanged.

Due to the similar characteristics of bi-directional DC-DC converter in boost and buck mode, the dynamic model of bi-directional DC-DC converter in boost mode is established and the corresponding controller is designed. With the rapid development of human society, economy and science and technology, people pay more and more attention to the lack of resources and environmental protection.

Many countries have introduced more stringent policies on energy and environmental protection. Bidirectional DC-DC converter can greatly reduce the volume, weight and cost of the system and improve the efficiency of the battery.

It has broad application prospects in electric vehicles, elevator operation, solar energy storage system, uninterrupted power supply (UPS) system and other fields, and has important research significance.

Two-way DC-DC converters are mainly divided into isolation and non-isolation topologies.

The main difference is whether there are transformers or not. Firstly, the isolated converter, which contains magnetic materials such as inductance, transformer and so on, makes the whole converter too large in volume, and the circuit is more complex.

The more components, the greater loss and the higher cost. So it’s not considered. Secondly, the converter with non-isolation mode has fewer kinds and quantities of components, simple and easy to control circuit, and small volume and high efficiency.

Therefore, this paper adopts non-isolation topology. The multiplex parallel converter can improve its working frequency, make the output voltage ripple smaller, and also improve the efficiency of the converter.

Moreover, the converter has a wide range of output voltage to meet the basic requirements of charging and discharging.

Therefore, the application of multiple parallel converters in energy management system will greatly improve the performance of the system.

Finally, two-phase interleaving bi-directional DC-DC converter is adopted, as shown in Figure 1.

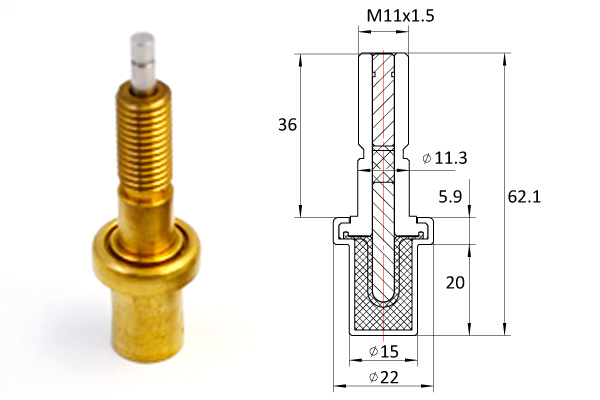

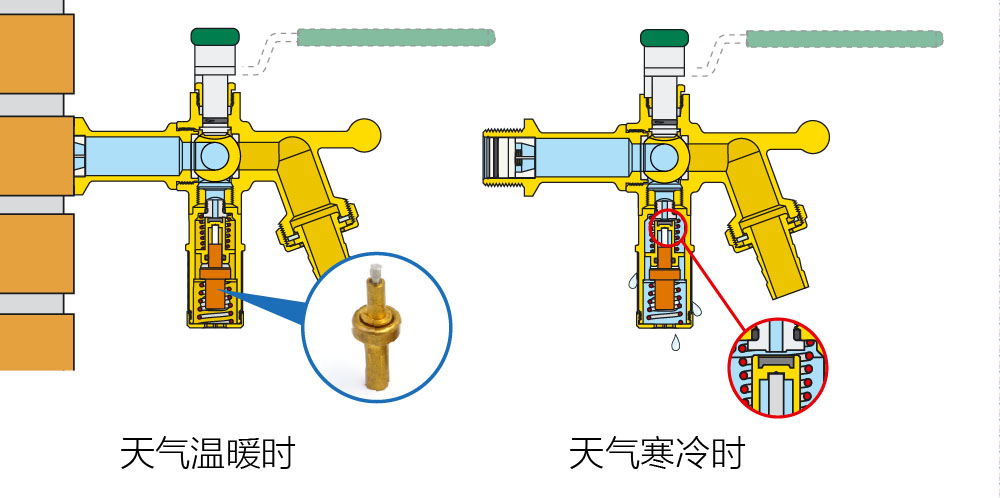

V1 (t) and V2 (t) can be regarded as continuous and approximately unchanged in a cycle, thermostatic element so they can be equivalent to the average value in Ts, that is, V1 (t) = {v1 (t)}, V2 (t) = {v2 (t)}.

D’1 = 1-d1, d’3 = 1-d3. In the steady state of the converter, assume D1 = D1 (t), D3 = D3 (t), V1 = {v1 (t)}, V2 = {v2 (t)}, IL1 = {iL1 (t)}, IL2 = {iL2 (t)}.

The circuit works in Boost mode. In order to provide power output quickly and keep bus voltage stable, the control is based on the double closed-loop method of voltage and current. The DC bus voltage is real-time detected by the voltage outer loop, and then compared with the given constant voltage as the voltage outer loop to stabilize the output voltage.

At the same time, its output is modulated by PI as the current inner loop. Given current. The control block diagram is shown in Figure 2. After PI compensation, the overshoot of the output voltage of the converter is improved, the response speed of the output voltage is increased, and the steady-state error is reduced. Therefore, the design of the double closed-loop controller in this paper is reasonable and can improve the overall performance of the converter very well.