From the knowledge of aquaculture, we know that oxygen is one of the essential conditions for the survival and growth of fish. Oxygen content in water is mainly related to natural temperature, humidity and fish density. Fish are very sensitive to oxygen content in water. The traditional way of aquaculture is to judge whether the water is hypoxic by observing the floating head of fish according to experience. In order to prevent the occurrence of pan-ponds, fishermen need to spend a lot of time and energy observing the situation of the ponds.

This method has some shortcomings, such as post-control, inadequate or excessive oxygen enrichment, time-consuming and high labor intensity, which to some extent affects the growth of fish and increases the cost of aquaculture.

In order to improve the quality and quantity of fish products, enhance the automation level of aquaculture technology, reduce the labor intensity of fishermen, and reduce the cost of aquaculture, the dissolved oxygen automatic controller is used to monitor the oxygen content and temperature in water in real time, and the aerator is automatically activated to increase oxygen content and temperature in the water of fish pond. Keeping the lower limit within a set range can not only solve the problem of fish floating head caused by hypoxia in pond culture, but also eliminate harmful gases, promote convective exchange of water, improve water quality conditions, reduce feed coefficient, increase the activity and primary productivity of fish ponds, thereby increasing stocking density and feeding intensity of aquaculture objects. Promote growth, increase yield per mu by a large margin, and fully achieve the purpose of raising income. Many people in aquatic industry in China know the importance of using aerators. More and more people in domestic aquatic industry use aerators. However, many people don’t use enough, and they don’t realize that they have to use the aerator every day, and they don’t realize that they have to use the oxygen-tolerant automatic controller. When the aquatic products are hypoxic, such as fish swimming to the surface to breathe, it’s too late to add oxygen. If oxygen is not enough, the growth of fish will be hindered and the resistance will decrease significantly.

Experiments show that proper aeration of fish ponds will bring huge economic benefits. For example, in an experiment in the United States, compared the aerobic catfish pond with the non-aerobic pond, the aerobic pond made 92% more profit under the same investment; in another experiment in Asia, the aerobic shrimp pond and the non-aerobic shrimp pond were managed in exactly the same way. In aerobic ponds, the yield of shrimp is 188 kg/mu, while in non-aerobic ponds, it is only 136 kg/mu. The return of aerobic shrimp ponds is 42% higher than that of non-aerobic shrimp ponds. The dissolved oxygen automatic controller is composed of aerator, dissolved oxygen sensor, acoustooptic alarm circuit, etc. It can monitor oxygen content in pond in real time, control the working state of aerator, and remind staff to pay attention to the operation of relevant equipment and the real-time situation of fish pond. When in use, the aerator is placed in the non-feeding area in the center of the fish pond, the probe of dissolved oxygen sensor is placed at the edge of the fish pond and 0.5m below the water surface in the non-feeding area, and the control system is placed in the control room on the shore. Oxygen content sensor transmits the oxygen content information collected in water to signal processing circuit in real time. After amplification and filtering, it is sent to dissolved oxygen control circuit, which drives the aerator and acoustooptic alarm circuit to work. It can automatically monitor and control the start and stop of the aerator according to the upper and lower limits set by users, when dissolved oxygen is below. Start the aerator when the lower limit is higher than the upper limit. Close the aerator when the dissolved oxygen is higher than the upper limit, so as to keep the dissolved oxygen content in the set optimum state. Aerobic principle of aerator.

When the aerator is in operation, the impeller sucks up the oxygen-poor water in its lower part and pushes it out around to make the dead water become live water. Because of the strong stirring of the blades and pipes, the water under the impeller causes huge waves on the water surface, and forms a water curtain which can wrap in the air, enlarges the contact table of the gas-liquid interface, at the same time makes the double film between the gas and the liquid thinner and constantly renews, which speeds up the dissolution of oxygen in the air into the water. Importantly, the aerator also desorbs harmful gases such as H2S, ammonia, methane and SO2 from water through aeration while stirring. In the process of rotating the impeller, negative air pressure is formed at the back of the stirring pipe, so that air can be sucked into the water through the stirring pipe, and is quickly stirred into micro-bubbles into the impeller pressure zone, so it is also helpful to improve the dissolution rate of oxygen in the air and the efficiency of oxygen enrichment in the water body. Type and scope of application of aerator. According to the above principles, there are many types of aerator products designed and manufactured, and their characteristics and working principles are also different. The aeration effect is different and the scope of application is different. The aquaculture users can choose the appropriate aerator according to the demand of dissolved oxygen in different aquaculture environments or systems to obtain good economic performance. Inhalation aerator: Based on negative pressure suction, air is fed into water and mixed with water to form eddy current to push water forward, so the mixing force is strong. It has better aeration performance for lower water than impeller aerator, and slightly lower aeration performance for upper water than impeller aerator. Jet aerator: This aerator is composed of submersible pump and jet tube. When working, the water in the pump is ejected at high speed from the nozzle in the jet tube, which produces negative pressure to inhale air. The water and air are mixed in the mixing chamber, and then pressed out by the diffuser, the dissolved oxygen will diffuse along with the water flow in the straight line direction. Because the aerator has no rotating mechanism under water, it does not harm the fish body, and is suitable for deep-water fish ponds with high fish density.

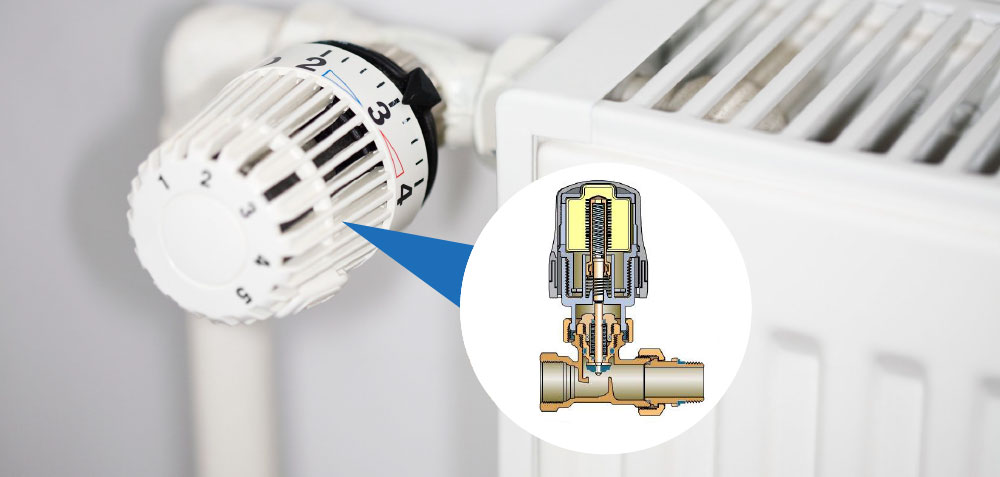

Water truck aerator: When the machine works, thermostatic element the blade hits water at high speed, stirring air into water to achieve the purpose of aeration. This aerator is suitable for shallow ponds. It does not stir the sediment and keeps the water fresh. Water truck aerator: It has good effect of aeration and water flow promotion.

It is suitable for ponds with deep silt and an area of 1 000-2 540? Water-jet aerator: This machine uses water pump to send water into the sprinkler installed in the middle of the fish pond and the shore, so that water sprays out and falls in the form of rain, so that water and air contact to achieve the purpose of increasing dissolved oxygen. This machine is only suitable for small shallow fish ponds. Eddy current aerator: It is mainly used for aeration of subglacial water in northern China, with high aeration efficiency. Air-filled aerator: The main engine is an air compressor or blower. When the air is pressurized through sand filter core or micro-porous plastic pipe installed under water, micro-bubbles are discharged, and water movement is formed during the rising process of bubbles. Some oxygen is dissolved into water to achieve the purpose of oxygen enrichment. The machine is suitable for deep-water fish ponds. With the continuous refinement of fishery demand and the continuous improvement of aerator technology, many new aeration machines have appeared, such as surge aerator, spray aerator and so on.

The equipping principle of aerator. The principle of selecting and matching aerator is not only to fully meet the need of dissolved oxygen for normal growth of fish, effectively prevent dead fish from hypoxia and deterioration of water quality, reduce feed utilization rate and growth rate of fish, and cause fish disease, but also to minimize operating costs and save expenses. Therefore, the selection of aerator should be based on the depth of the pond, different fish pond area, farming unit yield, aerator efficiency and operating costs. According to the determination, the total oxygen consumption per kilogram of fish per hour is about 1.0 G. Among them, the oxygen consumption of life activities is about 0.15 g, and that of food digestion and excreta decomposition is about 0.85 G. Taking a 10 mu intensive fish pond as an example, the equipment of aerator is shown in Table 1 above. The function of aerator to improve the ecological environment of pond is mainly manifested.

When the fish pond is short of oxygen, it can prevent fish and shrimp from floating. When the dissolved oxygen in the upper layer is high on sunny day, it can accelerate the convection of water, improve the dissolved oxygen in the middle and lower layers of water, help fish and shrimp to grow rapidly, reduce the feed coefficient, promote the oxidative decomposition of organic matter, and reduce the occurrence of diseases. In addition, the circulation of water also promotes the reproduction and growth of plankton and improves the primary productivity of ponds. It can be seen that the role of aerator is not only to increase water oxygen, but also to effectively promote the improvement of primary productivity and self-purification capacity of ponds, thus improving the water quality and ecological environment of ponds.

The water circulation is not suitable for the living habits of some aquaculture objects such as eels and shrimps, but it has a good effect on promoting the healthy and rapid growth of fish and shrimp. The dissolved oxygen automatic controller can make the dissolved oxygen content of fish pond moderate, ensure the normal growth of fish and shrimp, reduce the occurrence of fish and shrimp diseases and anorexia, improve feed input coefficient, save manpower and energy. In the process of fish and shrimp culture, dissolved oxygen in water can be increased and water quality can be improved, floating head death of fish and shrimp can be prevented, breeding density can be increased, and fish growth can be accelerated, so as to achieve high and stable yield. Author’s brief introduction: Hu Rongfang (1973-), female, Han nationality, Dafeng people in Jiangsu Province, Liuzhuang Town Agricultural Technology Extension Comprehensive Service Center, Yancheng District, Jiangsu Province, engineer, undergraduate, has been engaged in Aquatic Technology Extension work.