In order to solve the problem that the traditional PID parameter optimization method is prone to time-consuming, oscillation and can not guarantee the optimal tuning parameters, a method of optimizing the parameters of PID control based on Dragonfly algorithm is proposed. This method uses the process of dragonfly population searching for food and takes ITAE as its fitness function to optimize the parameters of PID control.

。 The simulation results show that the PID controller based on Dragonfly algorithm has better control performance than other commonly used PID parameter tuning methods such as particle swarm optimization, artificial bee colony algorithm and cuckoo search algorithm. The PID controller is one of the earliest feedback controllers. In the field of industrial control, more than 95% of the feedback loop components use the PID controller.

However, because the essence of the PID control is a linear control law, the conventional PID control effect is not good for some complex systems with nonlinearity, high order and time delay in practical industrial applications. It can meet the production requirements. Therefore, the parameter optimization of the PID controller has always been an important subject in the control theory research. Dragonfly Algorithms (DA) [2] are derived from the swarm behavior of dragonflies in nature to optimize the objective function. This algorithm not only possesses the personal and social cognitive abilities of particle swarm optimization, but also combines the flight behavior of [Le’vy] in cuckoo algorithm [3].

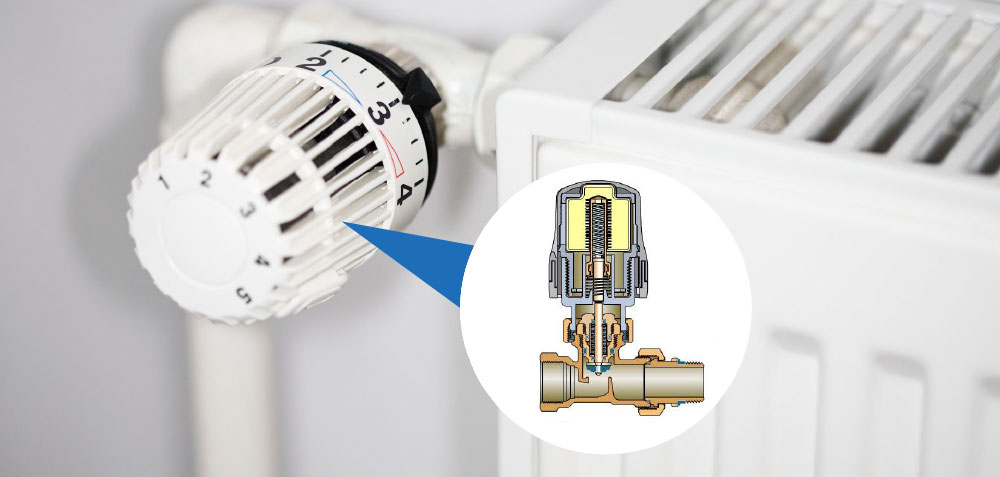

It can effectively avoid falling into local optimum and improve the search performance of the algorithm in the process of optimization. In this paper, Dragonfly algorithm is used to optimize the parameters of the PID controller. The basic idea is to take the parameters of the PID controller to be optimized as the position information of the individual dragonfly, and take the error performance index ITAE as its fitness function. The typical control models of seven kinds of industrial control are selected and simulated by matlab. The simulation results are compared with several commonly used PID parameter optimization methods such as particle swarm optimization [4?6], artificial bee colony algorithm and cuckoo search algorithm. The experimental results show that the PID controller optimized by dragonfly algorithm has good control performance for each control model. Considering the randomness of the intelligent optimization algorithm, under the same environment, each algorithm carries out 20 independent simulation experiments for seven different control models, and carries out different algorithm analysis from the optimal value, thermostatic element the worst value, the average value and the variance of the tuned ITAE performance index results.

The results are shown in Table 3. From Table 3, we can see that for the controlled objects [G1 (s)], [G3 (s)] and [G5 (s)], the simulation results of dragonfly algorithm are superior to the other four algorithms in the optimal value, the worst value, the average value and the variance; for the three controlled objects [G2 (s)], [G4 (s)] and [G6 (s)], the optimal value, the worst value and the average value of dragonfly algorithm are superior to other comparative algorithms; 7 (s)] For non-minimum phase systems, the optimal value of dragonfly algorithm is slightly worse than that of particle swarm optimization, but it is better than particle swarm optimization and other comparative algorithms in terms of worst value, average value and variance.

Comparing the data in Tables 2 and 3 and the evolutionary curves of performance indicators in Fig. 1-7, considering the performance indicators, response time and applicability, the algorithm in this paper is obviously superior to the other four algorithms for seven kinds of typical controlled systems. To overcome the shortcomings of traditional PID tuning methods, such as poor portability, time-consuming and unable to guarantee the optimal control performance, a new PID controller based on Dragonfly algorithm optimization is proposed.

Taking advantage of the strong optimization ability of dragonfly algorithm, the position of dragonfly is defined as three parameters of PID controller, and the process of hunting for prey by dragonfly population is regarded as the optimization of PID control parameters. In Simulink environment, the ITAE performance index corresponding to each group of control parameters of the PID control system model deserves the optimal control parameters to control the controlled system, which has strong adaptability and robustness.

In this paper, seven kinds of commonly used industrial control systems are selected for simulation experiments.

The experimental results show that the PID controller based on Dragonfly algorithm has better control performance and robustness. Therefore, it has good application prospects in industrial control. Note: The author of this paper is Huang Quanzhen.