From the point of view of saving cost and improving the utilization rate of chip resources, this paper designs an automobile body controller with integrated gateway function, which not only realizes the basic function of the automobile body controller, but also realizes the function of the automobile gateway controller. The algorithm is developed by using the fast prototype product of dSPACE.

Finally, the body controller model developed in this paper has passed the bench test and the vehicle test.

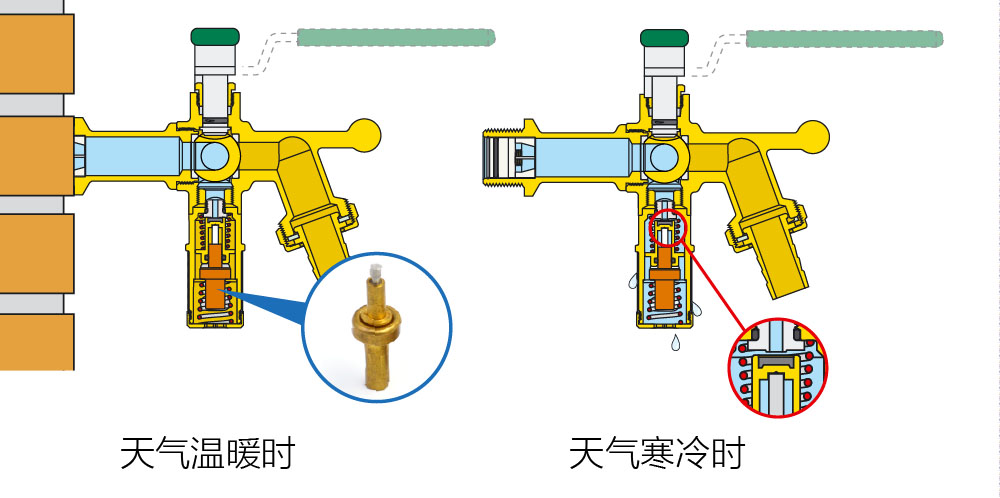

The experimental results show that the body controller of the integrated gateway can realize the functions of the body controller and the gateway controller, and has good practical value. With the increasing popularity of family cars in China, the degree of automotive electronic integration is also increasing. For automotive itself, thermostatic element the increasing communication between electronic controller modules can not be achieved through simple physical hard wire connection.

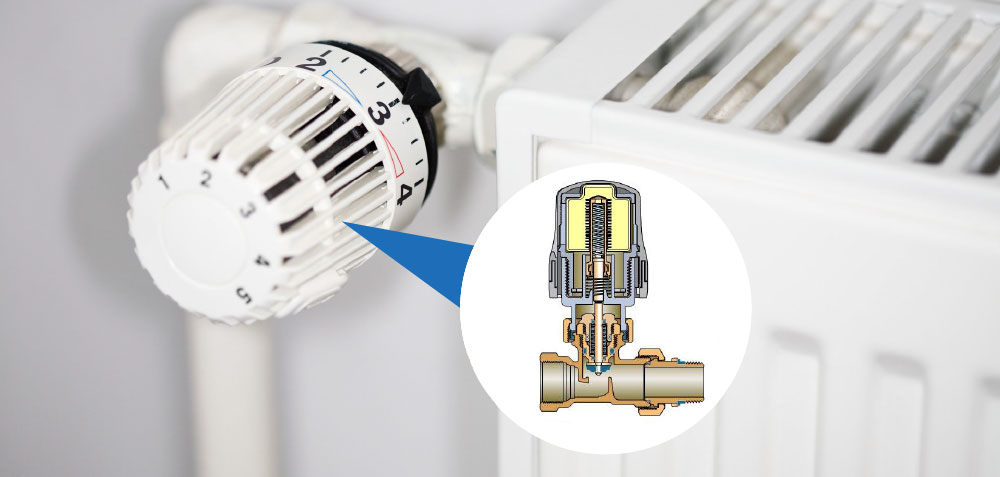

Based on this background, automotive CAN bus technology has been deeply developed and widely applied. The function of a single automobile gateway controller is single, but the development cost is not low, and the function of the gateway is indispensable. Therefore, from the point of view of cost saving, considering that integrating this function into other functions is relatively simple, the control unit with low utilization ratio of the controller has become an inevitable trend. In order to meet people’s increasing requirements for convenience and comfort, various electric control functions emerge as the times require, such as electric window control function, intelligent wiper control function, electric seat ventilation and heating function, etc. [1]. The control logic of these functions is not complicated, but it is directly related to the perceptual experience of passengers and drivers. Any improper operation logic may lead to bad evaluation of cars by customers. In the long run, it may affect the position of cars in the market [2]. At the same time, the control logic of body controllers in different automobile factories is different. Even in the same manufacturer, the control logic of different platforms is different.

In order to meet the development needs, the automobile factories can only develop repeatedly, which directly leads to long development time, high cost of research and development, and the risk of programming errors. In summary, the gateway function and the body controller function are integrated into a controller, collectively called the body controller. Then, the model-based development technology is applied to the development of the body controller to solve the problem of repeated development. At the same time, the model-based development technology can also increase the control ability of software quality. Fast development process, reduce costs, improve product quality and enhance their market competitiveness. The continuous progress of electronic technology has led to the increasing demand for automotive capability improvement. This inevitable trend of electrical integration has made the original hard-wire communication technology unable to adapt to the direction of automotive technology development. Therefore, at the end of 1980s, Bosch Germany Company solved the real-time number between many control units and test instruments in modern automobiles.

A serial communication protocol CAN has been developed for data exchange, and it has become an international standard (ISO11898) [3]. The emergence of CAN bus technology eventually led to the intellectualization of vehicle body control network [4]. Unlike traditional hard wires, CAN bus technology has high reliability, easy maintenance, and greatly reduces the number and volume of wire harness, which is very helpful for vehicle lightweight. In addition, the greatest advantage lies in the flexibility of the system. Functional changes do not need to be achieved through hard-wire connections, but through software [6]. The rapid prototyping product is Microsoft AutoBox II of dSPACE. The unique advantage of this hardware system is that it integrates powerful performance, comprehensive automotive I/O interface, extremely compact and robust design (conforming to ISO 16750-3:2007 extreme impact and vibration test) and reasonable price.

These characteristics are the basis for selecting this rapid prototyping product. At the same time, the rapid prototyping product has been widely used in the automotive industry. It can optimize the development process, standardize the use of programming language, and avoid the time cost and risk cost of hardware development through a good hardware system, thus greatly improving the speed of product development. It has good pre-validation function and meets the requirement of frequent changes in the later period. The data used in the body controller development platform, the algorithm development software, the integrated test hardware and the relationship between the test systems are shown in Figure 1. The function specification is to define the function that the controller is to achieve, and it is the starting point of development. The functional specifications of different models will be different, but the differences will not be very big. The RTI of Simulink and dSPACE is used in the algorithm development. With modular design idea, it is quite convenient to change the program. After the algorithm development, it is downloaded directly to the new hardware products of rapid prototyping for bench and vehicle testing. The test tool used is CANoe. In this way, each module constitutes an organic unity. Once the platform test passes, only a small amount of algorithm adjustment according to the requirements of functional specifications is needed for subsequent re-development, which has good practical value. Figure 2 shows the system structure of the body controller with integrated gateway function.

The gateway function module designed in this paper includes high-speed CAN and low-speed CAN. Among them, the high-speed CAN is the automotive power CAN, which mounts the controller that concerns safety and requires high communication speed. There are engine control system (EMS), airbag control system (ABAG), anti-lock brake system (ABS), body dynamic stability system (ESC), cruise speed control system (STE). Low-speed CAN is a car body CAN. It mounts a controller with low speed requirement, which is related to the comfort of the car body. The main electronic control units are the combined instrument control system (IPC), the air conditioning controller (CCU), and the multimedia control system (MHU). The function of body control is mainly to collect all kinds of input signals (including digital switch, analog signal, pulse signal, etc.) and all kinds of lamps (including steering lights, position lights, indoor lights, far and near lights, overtaking lights, front and rear fog lights, brake lights, etc.) signals, remote control electric door lock, wiper, window and other control signals. 。 After the successful acquisition of various signals, the control logic designed by the functional specifications is used to make judgments, and then the control signal is output to the power amplifier module to drive relays, buzzers, lamps, motors and so on. According to the previous section of CAN network design, this section uses the Simulink and stateflow module of MATLAB and RTI module of dSPACE to develop the control algorithm of the body controller. Figure 3 is the algorithm model of the body controller, which is divided into two parts. Message Center is responsible for the gateway function and BodyControl Logic is responsible for the body control logic algorithm. After the completion of the program design, the tester and the developer jointly carry out the test and verification, which is divided into three steps: the first step is debugged by the programmer using the debugging function of simulink, and then the basic communication function of the control design test system is used. This stage is the category of white-box testing. The second step is the bench test.

The test team compiles test cases according to the functional specifications, and then carries out the overall test on the bench. The other relevant controllers are all actual controllers, which simulate various working conditions of the vehicle for cyclic test. This stage of testing belongs to the category of black-box testing. The test bench is shown in Figure 5. Finally, through this test procedure can be sent to the parts manufacturer for batch production.

The vehicle controller developed in this paper integrates gateway function and develops with rapid prototyping products. On the one hand, it is equivalent to two controllers being developed simultaneously. On the other hand, the development process is standardized, which not only saves the development cost, but also speeds up the development process of subsequent products. Finally, the product developed in this paper has undergone triple testing, and the related requirements of the original functional specifications have been realized, which verifies the practicability of the program.