With the rapid development of science and technology, the development of automotive electronic technology is also very rapid. Consumers pay more and more attention to the automotive glass lifting system, and put forward higher requirements for its operation reliability and efficiency. Therefore, the glass lifting control system needs to be more intelligent.

In this paper, the controller of glass lift control system is designed intelligently. The controller is equipped with processor and communication chip. It focuses on improving the efficiency and reliability of the system function. At the same time, the system is more easy to operate and more humanized. In recent years, China’s automotive industry has developed rapidly, and the development of automotive electronic technology has made great strides. In addition to the rapid development of multimedia audio and other on-board entertainment systems, the control mode of automotive basic subsystems, such as door, lamp and window glass, has gradually changed from the traditional, simple and hard-wire control mode to make. All kinds of controllers and relays are used to realize the control. The lifting system of automobile window glass is a component with very high frequency used by consumers in the process of using vehicles. The ease of operation, reliability and stability of lifting control greatly affect the experience of consumers. In the course of the development of automobile electronics, the lifting of window glass has also experienced a change from manual control to electric control.

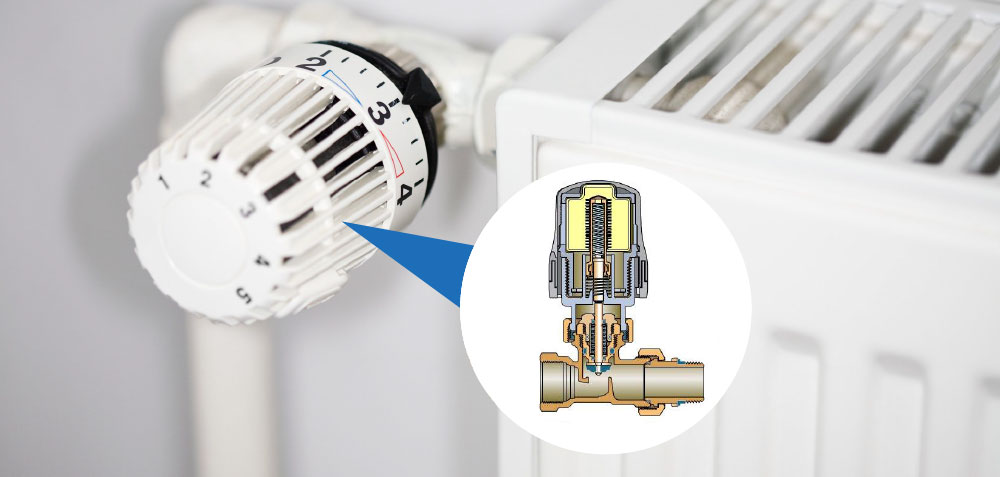

With the popularity of automobiles, consumers put forward higher requirements for the rise and fall of automotive window glass, which requires more convenient operation, more humane performance, more reliable system operation and lower failure rate. Therefore, the demand for intelligent automotive window glass controller is growing. In view of this, the article puts forward a new scheme for the control of window glass. Glass lifting system is an important part of automotive operating system. In the process of rapid development of automotive intelligent technology, automotive glass lifting control system is also developing towards intelligent direction. As shown in Fig. 1, the automobile window glass lifting control system based on LIN communication consists of four parts, including window glass lifting signal, glass lifting controller, window glass lifting motor and other communication equipment.

Among them, the controller is the core component of the automobile window glass lifting control system.

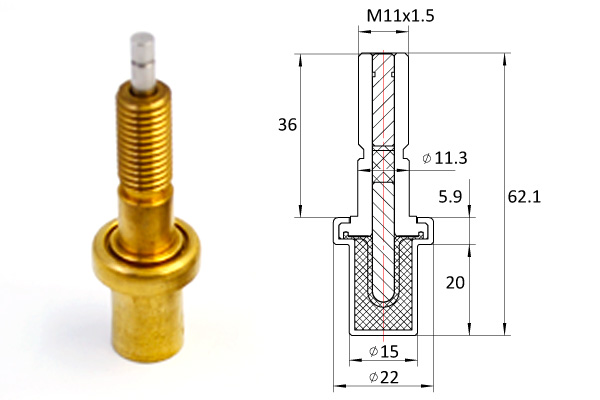

It also contains many different functional modules, including single chip computer (CPU), relay and current detection circuit, as well as LIN chip used to communicate with external equipment. As the core component of intelligent automobile glass lifting controller based on LIN communication, the processor shoulders heavy responsibilities. Its main function is to receive the glass lifting switch signal, other external glass lifting control signal (such as remote control key’s remote control lifting/falling glass signal), and process the signal, then carry out logical operation, and then according to the operation. The result of calculation gives the relay the correct output signal. The relay electrifies to drive the glass elevator motor to complete the glass up/down action. The process logic block diagram of its function is shown in Fig. 2. Fig. 2 shows that the processor must first correctly identify the glass lifting control signal and remove the invalid interference signal, that is, the processor needs to have the filtering function of the input signal; secondly, on the premise of correctly identifying the input signal, thermostatic element the processor needs to carry out accurate and high-speed logic operation; finally, according to the results of the logical operation, the relay is positioned. Exact output signal. In order to better meet these control functions, glass lift processors need to have very high hardware configuration and high precision analog level, as well as high performance digital signal processing capabilities. In view of this, the ST series chip STM8S003 is mainly used in the design. The processor core is 8 bits, the main frequency is 16 MHz, and Flash is 8 K. It is a high performance digital hybrid processor. It can process various external signals well, and the logic operation is accurate and high-speed. It can ensure that the glass lift control system works fast and reliably. Under the general working condition of automobile, the current in the glass lift control motor is 6-8 A and the stop-up current is about 10 A. In some harsh situations, such as cold weather, hardening of rubber strips on doors, or longer service time of automotive glass lifting system, the resistance of glass lifting process will increase after parts aging and degradation, the current in glass lifting control motor will also increase, and the blocking current may be as high as 18 A. The load capacity of other electronic components on the PCB board of the controller is far from meeting this requirement, and the output current of the CPU is only milliampere level, which can not drive the motor to run normally; moreover, the blocking current of the glass lift control motor is enough to burn all the electronic components on the PCB board.

Therefore, the current conversion module must be used in the design of the controller to convert the milliampere current output by the controller into a large current which can drive the glass elevator motor. Based on this, relays are used for current conversion in the design. Panasonic CT series relays are selected. Under rated condition, the operating current of the coil end is only 66.7 mA, the suction time and release time are less than 10 ms, but the rated current output of 20A can be provided in time and reliably. The control output of the processor is transmitted to the control motor of the glass elevator to make the system run normally. From the above analysis, it can be seen that under the non-ideal situation, the blocking current of the motor is quite large, and the long-term high current is extremely harmful to the controller and motor in the glass lifting system, which seriously affects the service life of the controller and motor and the reliability of the system operation. Therefore, when the motor is blocked, some protective measures are needed, that is, the glass lifting controller needs to have the motor blocking protection function. In order to realize motor stop-up protection, first of all, the controller needs a current feedback circuit. There are sensors to detect the current in the circuit to identify whether the motor is in stop-up state or not. Secondly, when the motor is identified to be in stop-up state, the output needs to be cut off quickly to cut off the circuit current and interrupt the current action. The specific working logic is shown in Figure 3. As can be seen from Figure 3, the following three key points need to be clarified. Ia-setting of current limit for blocking. Setting a reasonable stop-up current limit for the controller, that is, when the current value in the sampling sensor is greater than or equal to the current limit, the processor considers that the motor is in the stop-up state, and will cut off the output to interrupt the current work to protect various parts of the glass lifting system; when the current value in the sampling sensor is less than this When the current limit is applied, the processor assumes that the current glass has not been raised or lowered in place, and that the current output state should be maintained. Therefore, the setting of motor stop-up current limit affects the reliable operation of the whole system. If the setting is too large, the system will be damaged; if the setting is too small, the system can not operate reliably. So how to set the limit of blocking current (Ia) correctly? It is necessary to set specific settings for different types of vehicles and calibrate the glass lifting system, that is, to set reasonable blocking protection current by calibrating the working current and blocking current of the motor under different conditions. Specific calibration process is as follows: {1} low temperature operating conditions – in low temperature (-10 C, -30 C) environment, the motor in the actual door system on the current curve, including motor start current, normal working current, stop-up current; {2} normal temperature operating conditions – at room temperature (20 C) environment, the motor in the actual door system on the current change curve. Wire, including motor starting current, normal working current, blocking current; {3} high-temperature conditions – in high temperature (85 C) environment, the motor in the actual door system of the current change curve, including motor starting current, normal working current, blocking current. The controller needs to identify the current of the motor accurately. In this paper, A/D sampling is used to sample the current of the current motor. The sampling current has high precision.

Cut-off time setting. When the processor detects that the motor is currently in a blocked state, it needs to cut off the circuit current quickly. In this paper, the time is set to 1 s according to the actual use of the glass lifting system and the CPU crystal frequency of the controller. Intelligent automotive glass lifting controller can not only work inside the system, but also communicate with external devices, such as body controller or transmitter/receiver of other signals, so as to control the rise and fall of glass more intelligently. In this paper, according to the reliability of each bus communication mode and the actual demand of system application, LIN communication is selected for the controller. The LIN transceiver uses TJA1028 of NXP. The transceiver has an integrated regulator. Its bus output is designed to withstand high voltage. It can provide strong ESD and EMC. In order to reduce current consumption, it also provides sleeping mode. It can provide wake-up function through LIN bus, so that the design is more reliable. And intellectualization. The design of intelligent glass lift controller based on LIN communication also includes many details, such as the design of voltage stabilization circuit, which converts the 13 V working voltage provided by automotive electrical appliances into 5 V CPU working voltage, and eliminates the impact of the fluctuation of vehicle power supply on glass lift control. There are other peripheral circuits, such as reset circuit, clock signal circuit, memory expansion circuit, etc. These hardware circuits play a key role in the operation of intelligent glass lifting control system, ensuring the overall design of the system, and are an important part of the system. The advantages of LIN-based communication glass lift controller in processor design, motor drive design, motor stop-up protection and communication design are discussed.

In addition, there are many bright spots in LIN-based communication glass lift controller. As mentioned above, the intelligent automotive glass lifting controller needs to have the filtering function for the input signal. In this paper, a button filter is set up in the software. Only when the processor receives the glass lifting switch signal or remote control lifting signal and the duration of the signal is greater than or equal to 100 ms, it determines that the input of the glass lifting signal is valid. Otherwise, it is regarded as an invalid input signal and does not perform the glass lifting/falling action. This can effectively avoid some special cases of car glass lifting errors, such as when the vehicle is driving in poor road conditions, the car vibration is too large, the glass lifting switch button jitter causes the contact to be switched on immediately after disconnection; or when the driver or passenger accidentally press the glass lifting switch or remote control key, the signal is transmitted. The contact is immediately connected and disconnected. These two conditions will cause the controller to receive very short time glass lift control signal input, but because the input duration is too short (less than 100 ms), the controller considers that the glass lift input signal is invalid, does not perform any action, the function of the system is more reliable, and also guarantees the safety of consumers.

Through the research and statistics on the lifting process of automotive glass under different operating conditions, it is found that under the normal working conditions of automobiles (about 22 C at room temperature), basic 3-4 s automotive glass can be raised or lowered in place. In extreme adverse conditions (such as low temperature-30 C), it takes 6-7 s to finish. Cheng. When the glass rises or falls in place, the motor is in a stalled state. In order to increase the protection measures of the system, this paper sets up the delay protection function for the system at the time of design. When the glass has been continuously rising or falling for a period of time, the processor will directly cut off the output and interrupt the system’s ongoing actions, thus effectively protecting the parts of the system and improving the security level of system operation. With the rapid development of social science and technology, intelligent technology has also been widely applied in all walks of life. The expansion of various electrical functions will be the focus of consumers’attention to the use of automotive functions in the future, becoming automobile.