The air compressor thermostatic control valve element is used to inspect the temperature of oil system for air compressors. Once the oil temperature is too high, the piston of element will rise and therefore shut off the valve and stop the air compressor for protection.

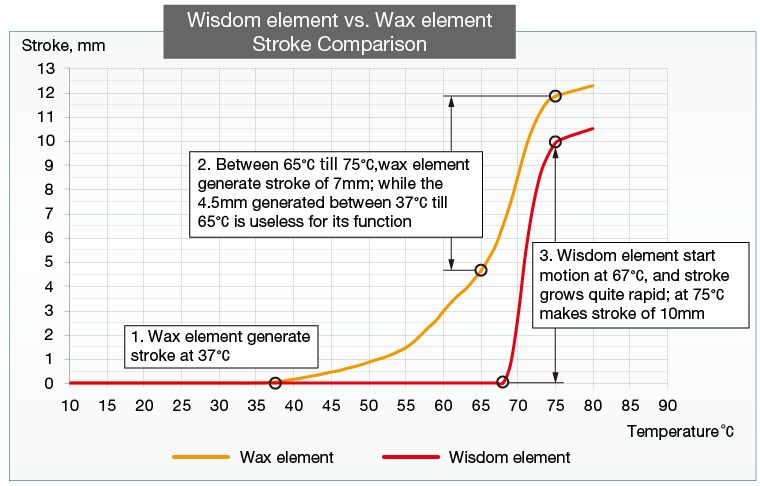

Wisdom recently made an experiment of temperature – stroke comparison beteen regular wax made element and wisdom product.

Sample: regular wax element and wisdom element, for temperature range of 65°C till 75°C.

Test condition: start from 10°C till 80°C, with load of 80N.

The stroke – temperature curve as below:

1. Wax element start generating motion at 37°C; while Wisdom element start moving at 67°C.

2. As for 65 – 75°C air compressor thermostatic element, the stroke length generated by wax element before 65°C is actually useless (above graph 4.5mm).

3. Wisdom element with superior tolerance of ±1°C; while wax element is only ±3°C or ±5°C.

4. In order to improve its thermal conductivity, there’s certain copper powder been mixed into the wax; however after thousands times of circulation of melting – solidification, the copper powder will gradually subside toward the bottom of element, eventually affect its performance. On the other hand, wisdom element have no foreign ingredients, as a result wisdom products with greater reliability.