Individual ammeter detectors are often used in low-voltage electric energy performance field inspection and other occasions. According to the technical requirements, this paper thoroughly analyses the causes of affecting the measurement accuracy and the solutions. In order to realize the real-time detection of voltage and current in power supply circuit, microcontroller is used as the core device of this paper. The single-phase supply current and voltage are transformed into weak electric signals by clamp current transformer and micro voltage transformer.

At the same time, the actual active power is measured by power metering chip, and the consumption of a certain time is calculated by making full use of the strong operation function of microcontroller.

Electrical energy. The error of ammeter is calculated by photoelectric sampler. With the progress of the times and the continuous improvement of people’s living standards, household appliances are becoming more and more popular. At this time, there is an urgent need for a single-phase meter detector with accurate measurement and simple operation to conduct on-site inspection of users’low-voltage watt-hour meters.

In this paper, microprocessor is the core, the measured watt-hour meter is sampled by photoelectric sampler, and real-time energy measurement is carried out by special chip for energy measurement and transformer. At the same time, the error of the measured watt-hour meter is calculated by microcontroller to ensure the accuracy of the watt-hour meter measurement.

According to the overall design requirements of the system, the schematic diagram of the system structure is shown in Figure 1. It includes voltage transformer (1) active power measurement channel; (2) photoelectric sampler; (3) microcontroller; (4) display; (5) keyboard; (6) composition. Converted to weak electric signal, then real-time acquisition of electrical parameters by computer and calculation of electrical energy.

The relative error of the measured watt-hour meter is calculated by sampling the measured watt-hour meter with a photoelectric sampler. This design displays information through LCD LCD screen.

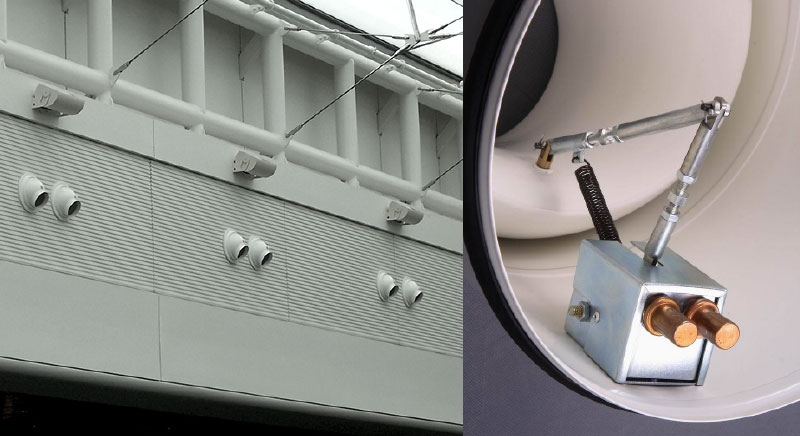

The display of information can be realized by programming with the character library. It has the advantages of high resolution, small weight, low power consumption and strong anti-interference ability. In this paper, the photoelectric sampler is used to detect the measured watt-hour meter. The photoelectric sampler is composed of three parts: light emitting tube, photosensitive receiving tube and shaping circuit. N denotes the turntable turning N, B denotes the turntable number, H denotes the mutual inductance ratio of the current transformer, then the energy measured by the watt-hour meter after turning N is shown in formula (1-1). The process is as follows: First, the current and voltage are measured, and then the measured results are sent to the CS5460 chip. Wi is the energy consumed in each sampling period, then the actual energy of the measured watt-hour meter after turning N, such as formula (1-2). The relative error of the watt-hour meter is displayed by the display part. The working state of the watt-hour meter is determined by the accuracy of the working error. The selection of display part should consider not only whether the number of digits it displayed meets the requirements, but also whether it is portable and can be read clearly in the harsh environment of strong light. AT89C51 is chosen for MCU, GST-4 for photoelectric sampler, Q8A for current transformer, miniature precision voltage transformer for voltage transformer, CS5460 for energy measurement chip, thermostatic element LCD1602 for display and 4*4 matrix keyboard for keyboard. The direction of CPU programs is changed by interrupting hardware. The handler that executes after an interrupt is called the interrupt service program [5].

This design is mainly keyboard interruption. The measurement error process is mainly to determine whether the relative error of the watt-hour meter is within the required range, so as to judge whether it works properly. The flow chart of measurement error is shown in Fig. 2. In order to improve the accuracy of measurement, piecewise linearization is used. Voltage transformer, current transformer and photoelectric sampler are used for field sampling of low voltage single-phase watt-hour meter. The accuracy of the meter is calculated by input the sampled value into the energy metering chip and then calculated by the single chip computer. When it is found that the meter measurement is inaccurate, the relative errors should be calculated in time; the detection of power lines is mainly carried out by voltage transformers and current transformers; and the judgement results and relative errors can be displayed by LCD to judge whether the meter is working properly.