The application of automatic humidity controller in programmable power system makes precise quantitative control of humidity regulating equipment such as dehumidifier and drying lamp in substation, so as to avoid the phenomenon that artificial control is not timely and the use time is too long. It not only improves the qualified rate of environmental humidity in substation, but also avoids the damage of humidity regulating equipment. In recent years, with the development of new technologies such as computers, communications, networks and batteries, the modernization and automation level of substations has been greatly improved. The computer monitoring and integrated automation system has replaced the conventional control mode, the computer protection has replaced the conventional electromagnetic protection, the valve-controlled maintenance-free lead-acid batteries have replaced the conventional lead-acid batteries, and even the operation and management of substations have been improved. The computer is paperless. More noteworthy is that with the continuous application of new technologies, these new devices have put forward higher requirements for environmental temperature and humidity. For the control of ambient temperature, air conditioning is mainly used in substation as a regulating tool, which can keep the temperature within the required range. However, the regulation of humidity is not ideal, there are two main reasons. First, the main tools for humidity regulation in substations are drying lamps, dehumidifiers and so on.

However, both of them need artificial control, which can not be adjusted according to the environmental humidity in time, leading to the preservation of safety tools in the environment that does not meet the humidity requirements, and easy to lead to the damage of safety tools. Second, due to the dehumidifier, drying lamp and other equipment can not be closed in time, resulting in its use time is too long, the effect is not obvious.

The dehumidifier will be idle, extremely easy to burn, maintenance or replacement will cost a lot of money. According to statistics, from January 2013 to December 2013, the qualified rate of humidity in the safety toolbox of 220 kV Zhongkai Substation is only 56%. After on-site inspection, thermostatic element it is caused by the failure of the dehumidifier, drying lamp and other equipment to start in time.

Therefore, how to improve the response speed of humidity regulating equipment is of great significance for improving the preservation environment of safety tools and preventing their damage. Through the analysis of station members, there are two solutions. First, we should start with the system.

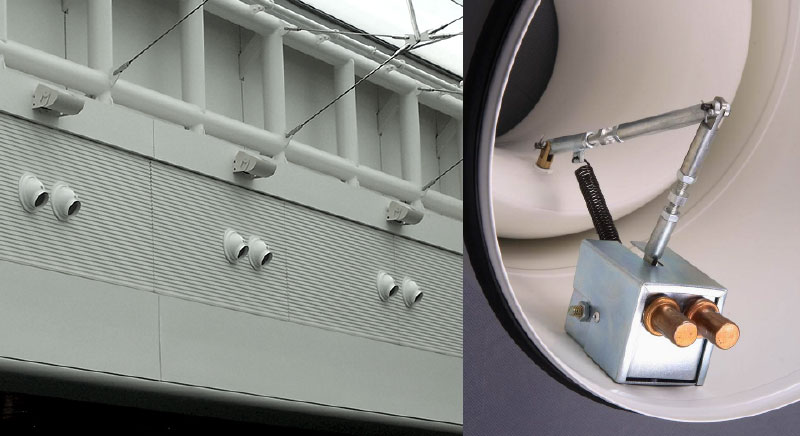

Operating and maintenance personnel are required to visit the safety equipment room regularly every day and open the dehumidifier and other equipment if the humidity is not up to standard. Although this method is the most economical, it will increase the workload of operation and maintenance personnel, and can not guarantee the effect. Second, start with technology. The power circuit of the dehumidifier is equipped with a programmable electric system humidity automatic controller. The device is easy to install and is directly installed in the power circuit. The humidity sensor is used to detect the environmental humidity in real time, and the microcontroller is compared according to the upper limit value set by the program. When the detected environmental humidity reaches the upper limit, the controller sends an order to drive the humidity regulating equipment to work until the lower limit of the environmental humidity is stopped, so as to achieve the purpose of quantitative control of the environmental humidity. The programmable humidity automatic controller of power system includes single chip computer circuit, humidity sensor circuit and power circuit control circuit. The upper and lower limits of humidity are set respectively. The humidity sensor detects the humidity value in real time and transmits the humidity value to MCU for processing. Comparing the upload value of humidity sensor with the upper limit and lower limit of humidity in MCU; when the humidity is greater than or equal to the set upper limit of humidity, the humidity regulating tool opens and dehumidifies; until the upload value of humidity sensor is less than or equal to the lower limit of humidity, the humidity regulating tool shuts down. The humidity sensor detects the humidity value in the environment in real time. When the humidity is greater than or equal to the upper limit of humidity, the humidity adjusting tool opens and the dehumidification operation is carried out until the humidity is less than or equal to the lower limit of humidity. Through on-site investigation and data collection, three alternative chips are proposed for the core components of the controller – single chip computer and sensor. Finally, the single chip computer chooses STC89C52 single chip computer, which is inexpensive and has low bit error rate. AM2301 sensor is selected as the sensor. Its measuring range is 7.5% to 99.9%, and its precision can reach 0.1%.

Subsequently, we draw the logic diagram of the programmable humidity controller in power system. According to the requirements and measures of the logic diagram, we designed the circuit diagram of the automatic control module by using the professional design software PROTEL 99 SE. According to the circuit diagram, the components are processed and welded. After the circuit is welded, the software is programmed and debugged by using C language and structured programming method. In order to determine the threshold of starting and stopping of the dehumidifier, three threshold schemes are proposed and tested.

In order to select the optimal scheme, we put forward two requirements for the test: 1. Relative humidity is in the range of 50%-80%; 2. Energy saving is optimal. The test methods are as follows: 1. Connect the power consumption tester into the plug of the dehumidifier to measure the power consumption; 2. Clean the water tank of the dehumidifier every half hour from the beginning of the test to ensure the continuity of the test; 3. The test time is 09:00 to 21:00 per day.

After two months of follow-up survey, we set the start threshold at 70%, stop threshold at 60%, the best energy-saving effect. Thus, the development of programmable humidity automatic controller for power system has been completed from design to shaping. After the application of the programmable power system humidity automatic controller, from January to November 2015, the qualified rate of humidity in the safety toolbox of 220 kV Zhongkai Station increased from 56% to 99%. There was no dampness in the safety appliances and no damage to the dehumidifiers and drying lamps. Taking Zhongkai Center as an example, the replacement of all dehumidifiers under the jurisdiction of Zhongkai Center will cost (1700-2700)*11=18700-29700 yuan, which is a considerable expense.

However, after the application of the programmable power system humidity automatic controller, the original dehumidifier can be retrofitted at a cost of 210 yuan.

Each dehumidifier will save (1700-2700) – 210 = 1490-2490 yuan, a total of 16390-27390 yuan. With the increase of the number of dehumidifiers, the cumulative economic benefit is higher. The popularization and application of programmable power system humidity automatic controller makes the humidity regulating equipment in the safety tool room can be controlled quantitatively. It not only saves a lot of manpower and material resources, but also precisely and effectively controls the starting and closing of humidity regulating equipment, and reduces the running time of equipment. The most important thing is to effectively eliminate the occurrence of dampness of safety tools, ensure the quality of safety tools, and maintain the personal safety of operation and maintenance personnel.

Since the qualified rate of humidity in safety toolbox of 220 kV Zhongkai Substation is only 56% from January 2013 to December 2013, this paper analyses the reasons of unsatisfactory humidity in safety toolbox, and draws the conclusion that the main crux is that the dehumidifier, drying lamp and other equipment can not start in time. After the application of the programmable electric system humidity automatic controller, we can quantitatively control the humidity regulating equipment in the safety toolbox, and also eliminate the damage caused by the reactive work of the equipment, reduce the workload of the operation and maintenance personnel, and ensure the personal safety of the operation and maintenance personnel.