Programmable Logic Controller (PLC) is a compulsory course with strong practicality in automation specialty.

Based on the Kunlun industrial control configuration software MCGS, this paper discusses the method of simulating the realization of PLC control object on the upper computer, and builds a course practice platform for the realization of PLC control system. Taking the vertical lifting stereo garage control system as an example, the system structure framework of the platform, the monitoring screen, the method of establishing data objects in real-time database, and the method of communication between PLC and configuration simulation software are given. Programmable Logic Controller (PLC) is a new type of industrial control device based on microprocessor. It is a general product that applies computer technology to industrial control field. It is specially designed for application in industrial environment. The course of “Programmable Controller” has strong practicality.

However, in the current course experiment teaching, there are the following problems: (1) There are fewer kinds of control objects on the experimental device, lack of scalability, and research limitations. For example, this institute adopts QSPLC series programmable control simulation experimental device developed by Zhejiang Qiushi Educational Equipment Co., Ltd. The simulation control objects include fountain, digital display, stage lighting, traffic lights, manipulator, four-storey elevator and so on. When other kinds of actual control objects are to be studied due to the needs of teaching or scientific research, new experimental equipment must be purchased again, which is not only costly, but also occupies more space and difficult to maintain. (2) The intuition is weak. Existing PLC experimental platforms mostly simulate the operation of controlled objects with the brightening and extinguishing of light-emitting diodes at different parts, and the display is not vivid and intuitive enough. (3) The system lacks a monitoring interface, can not realize human-computer interaction, can not dynamically display the state of objects and store data. Configuration software can quickly construct and generate PC monitoring system. It can collect data from the scene, have real-time and historical data processing, alarm and security mechanism, process control, animation display, trend curve and report output, and enterprise monitoring network functions. Therefore, it can provide users with solutions to practical engineering problems. Complete scheme and development platform. Configuration software has the characteristics of simple operation, short secondary development cycle and strong versatility [2]. Based on the general version of MCGS6.2 configuration software, this paper uses computer to simulate all kinds of actual controlled objects, and establishes the experimental platform of PLC control system by establishing communication between PLC and computer. The application of the experimental platform in the practical teaching and scientific research of PLC can make up for the shortcomings of the existing experimental equipment of PLC, greatly reduce the experimental cost and enhance the expansibility of the system. If new controlled objects are needed, only simple software operation is needed. At the same time, friendly real-time monitoring interface can be realized, which is vivid and intuitive.

Displays the current state of the object. The structure block diagram of PLC control system based on configuration software is shown in Figure 1. As can be seen from Figure 1, ladder diagram is written on the PLC programming software installed in the computer and downloaded into the PLC. In the computer configuration software MCGS, the configuration simulation control of the PLC control system can be realized by creating a project to simulate the controlled object, setting up communication interface, running trapezoidal diagram in the PLC, entering the operation environment of the MCGS and operating graphic objects such as buttons on the monitoring interface. After many investigations, the Institute purchased Mitsubishi FX2N-48MR series PLC. The number of input and output points of its control unit is 24 respectively. It has the characteristics of fast speed and high function of logical selection and positioning control. It is suitable for connection, analog control, positioning control and other special purposes among several basic components. Program capacity is built-in 800-step RAM (can be input comments), the maximum can be extended to 16K steps. PLC programming software uses GX Works2.

It is a complete series of Mitsubishi human-machine interface programming software developed by Mitsubishi Motor. It is a programming tool for the design, debugging and maintenance of PLC. Compared with the traditional GX Developer software, GX Works2 has more comprehensive functions, better operational performance, and more easy to use. The configuration software is MCGS 6.2 general version. Compared with other configuration software, it has many outstanding features, such as high reliability, good visualization effect, easy learning, better comprehensive performance, etc. Therefore, it has been successfully applied in steel industry, electric power industry, petrochemical industry, water treatment industry and other fields after a long period of time. The actual operation of the MCGS system fully reflects the high stability and remarkable effect of the MCGS system. MCGS software system has two parts: configuration environment and operation environment. Configuration environment is like a complete set of tool software. Users can design their own simulation and build their own configuration engineering in this environment.

The operation environment is based on the configuration Engineering designed in the configuration environment, which runs according to the user’s requirements and design objectives, and can see the operation effect intuitively. The relationship between configuration environment and operating environment is shown in Figure 2 [3]. Taking the PLC control system of vertical lifting stereo garage as an example, this paper introduces the realization method and functions of the system. The design steps of the system are as follows. Analysis of control requirements and functional requirements. The vertical lifting three-dimensional garage provides two functions: storage and pick-up. The flow chart of car storage control is shown in Fig.

3. The process of car retrieval is opposite to that of car storage in Fig. 3. It is sketched here. I/O devices are determined according to the number of I/O ports in the design, and I/O points are allocated reasonably. The system determines that there are 22 input ports and 18 output ports. The ladder diagram program is designed in GX Works2. Enter the MCGS configuration environment new construction project. Design login welcome interface. Create the configuration screen of the vertical lifting stereo garage, as shown in Figure 4. Add the required components and set their corresponding attributes, including animation attributes, button action attributes and so on.

In setting component attributes, attention should be paid to the logical relationship between the front and the back. Some motion control variables are repetitive, and some auxiliary relays need to be added as intermediate variables to distinguish the repetitive process. The implementation is only a static interface, which needs to establish data objects in the real-time database to display the movement status of each component. When setting properties, you can define the action type and set its parameters.

It should be noted that every component in the monitor screen should set up corresponding connection objects and be stored in the real-time database. Set up the communication connection between PLC and MCGS configuration interface. First, select the device configuration in the device window, double-click to enter, right-click the device toolbox, and click on device management to enter the list of optional devices. General serial parent device and Mitsubishi FX serial programming port are added respectively, and device properties are set. Note the choice of FX2N-CPU, device address 2. The components of the configuration screen are connected with the communication between the actual input and output ports. Fig. 6 shows the schematic diagram of some channel settings. Enter the running environment of MCGS. The simulation is carried out to check the correctness of the program and debug the system as a whole. The ladder diagram written in GX Works2 will be imported into PLC and connected with the communication of configuration MCGS. The running result of PLC is displayed in real time through the configuration screen. The user can debug the errors and problems in the ladder diagram repeatedly according to the current state of the animation until the system realizes all the control requirements.

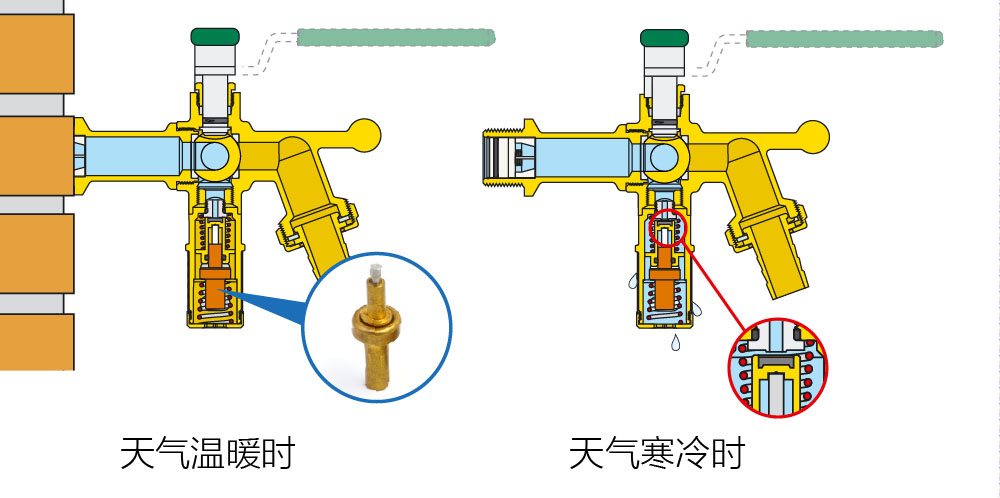

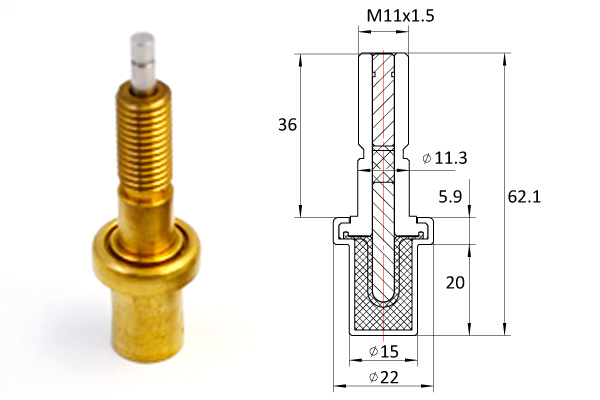

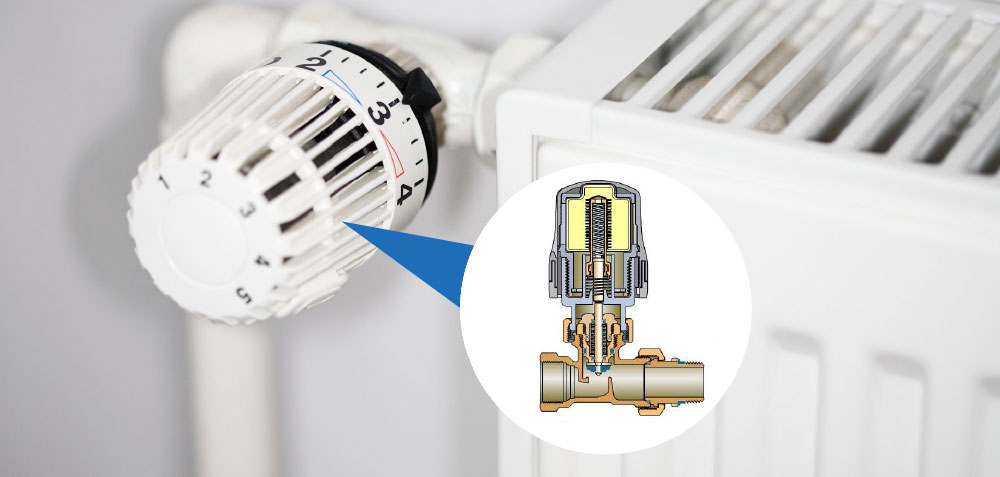

In addition to the three-dimensional garage, MCGS monitoring system based on PLC control is also designed and developed, such as self-washing garage, coin-operated automatic washing machine, five-storey elevator, electronic password lock, atmospheric pesticide filling production line and so on. The experimental method of PLC is universal, time-saving and labor-saving. For the same controlled object, thermostatic element if the control requirements change, only the ladder diagram needs to be modified accordingly; for the new controlled object, only the configuration animation is designed on the configuration software, and the corresponding ladder diagram is compiled, which greatly reduces the cost and risk of debugging the control system, improves the efficiency and security of system development, and maintains the system in the later period. Protection costs are also low. In addition, the way of animation display is vivid and intuitive, and the hardware connection of the system is very few. Compared with the traditional PLC experimental platform, the configuration monitoring system can achieve better simulation effect and practicability. The teaching reform of the practical link of PLC course has been one year. From the investigation and feedback to the students, it can be seen that the experimental platform is easy to operate, the students are easy to get started, the state of the controlled object is vivid and flexible, and the learning effect is good. It can effectively improve the students’ability to comprehensively use professional theoretical knowledge and independently analyze and solve problems. Power. On the other hand, from the perspective of teachers’teaching, the simulation of controlled objects by configuration software can greatly enrich the practical teaching content, reduce the cost of system development and maintenance, and promote the teaching of theoretical courses by teachers. In addition, the development of the experimental platform can also be used as a subject of graduation design or extracurricular research projects for students, and the results can be directly applied to the classroom practice teaching of PLC after improvement.