This paper summarizes a circuit with automatic turn-off and alarm for high voltage ignition extinguishing by stages, and briefly discusses its characteristics. In recent years, with the gradual improvement of road maintenance mechanization, various road maintenance equipment has been gradually used.

Temperature control of asphalt mixture used for road pit repair directly affects the repair quality. At present, the heating controller is an important part of asphalt mixture insulation equipment, which is used for short-time heating and insulation of asphalt mixture.

The well-known ignition controller is composed of a high-voltage ignition generator and an ion monitoring module.

There are the following defects in the use of this ignition device: firstly, it can not realize the graded ignition, and the direct ignition effect of high-pressure gas is not good; secondly, it can not cut off the gas in time when the fire is unexpected, and there is a certain danger; thirdly, the protective shell is relatively simple and unsuitable for the harsh environment in which the engineering equipment is situated. The circuit structure is complex and difficult to repair when the above functions are realized by the peripheral contactor, which results in great difficulty in maintenance.

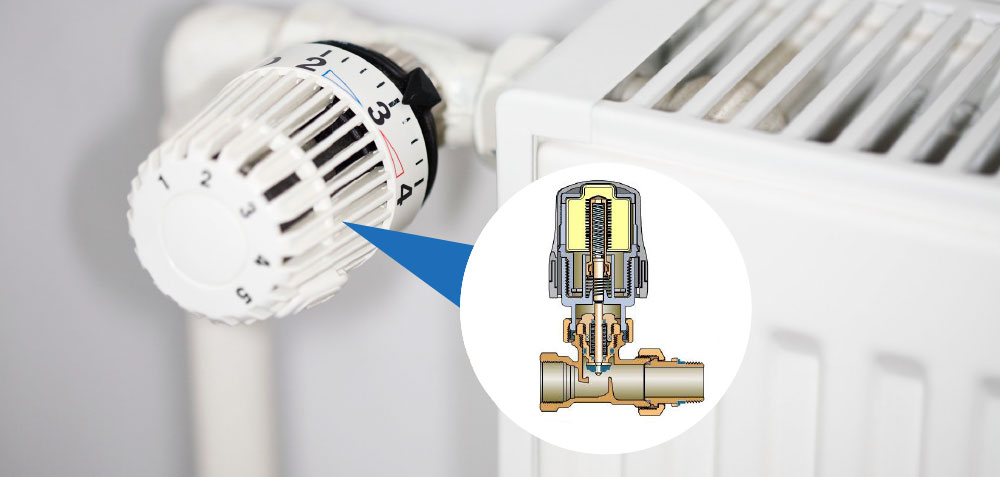

Overnight thermal insulation has great potential safety hazards, thermostatic element so it is difficult to achieve unattended automatic heating and thermal insulation.

The high-voltage pulse ignition and detection circuit is characterized by using 339 four-way voltage comparator, self-excited oscillation circuit and high-voltage coil composed of high-voltage pulse generation circuit and flame detection circuit. The ignition is aimed at the ground high voltage discharge to form an arc to ignite the gas, and the flame detection is realized by detecting the weak ionization state of the flame combustion. The alarm signal amplification and delay action circuit is characterized by using NPN PNP triode combination to realize signal amplification and delay circuit based on 555. Realize no ignition alarm, repeat no ignition cut off gas and issue an alarm. And control the gas valve on and off to prevent gas leakage caused by accidental flameout.

High-voltage gas delay opening circuit adopts delay circuit based on 555. As shown in Fig. 1, the ignition and heating controller for the asphalt mixture heat preservation transport box includes ignition and detection circuit, alarm circuit and graded ignition circuit. One end of the stop button’s normally closed contact is connected with 12V power supply, the other end is connected with the start button and is connected in parallel with KA3 to realize start-up self-locking to supply power for the circuit. The ignition and detection circuit part and the staged ignition circuit part are powered on. The ignition forms an arc to ignite the primary gas at the ground discharge point. The detector detects that the flame ignition circuit stops discharging, and the staged ignition circuit delays to turn on the secondary gas solenoid valve. When an accidental cease-fire occurs, the alarm signal is ignited. If the flame is not detected by one minute continuous ignition detection needle, the alarm circuit will be operated by K2.

K2 is connected with the K4 coil through diodes and forms parallel connection with the K4 and reset button. When K2 is operated, the K4 will automatically lock out the alarm signal and disconnect the K3 self-lock, and the power supply of the circuit will stop working. When the reset button is pressed, the circuit resumes its starting state. The control circuit uses the hierarchical ignition ignition to achieve better ignition effect and will not deflagrate in the flue, which improves the ignition effect; guarantees the safety of unattended on time; and makes the circuit more integrated and encapsulated safely.