It is of great significance to study the verification and debugging technology of DCS system in nuclear power plant for the development of nuclear power technology and the guarantee of nuclear safety in China. Traditional logic debugging work is carried out on the actual controller, which can not carry out efficient and complex logic debugging (such as PID adjustment, closed-loop logic control debugging, etc.

). Moreover, frequent experimental operation also has an impact on the life of hardware. To overcome the shortcomings of traditional testing methods, a method of using virtual DCS controller instead of physical controller in logic debugging of DCS prototype is proposed. Its advantages are as follows: 1) to operate the software of virtual DCS controller, the injection of signal is equivalent to the assignment of variables, and the operation is simple and efficient; 2) virtual DCS controller does not need hardware equipment.

The support reduces the dependence on equipment.

Logical configuration and engineering debugging can be carried out iteratively. 3) Virtual DCS controller can directly download and run DCS configuration engineering, and can be debugged in parallel with real DCS controller. The actual debugging results prove that DCS virtual machine can effectively complete the configuration logic debugging and improve the debugging efficiency. In recent years, the construction scale of domestic nuclear power plants has been increasing, and DCS system is adopted as the production control system in newly built nuclear power plants.

Therefore, it is of great significance to study the engineering debugging and verification technology of nuclear power DCS system for the development of nuclear power technology and the guarantee of nuclear safety in China. Because the high efficiency, safety and stability of nuclear power DCS system are related to the safety and benefit of nuclear power plant operation, it is necessary to build the engineering prototype of DCS system for comprehensive and complex logic debugging before the DCS system is put into operation. The traditional logic debugging work is carried out on the actual controller. The input signal is injected into the controller through short wiring or signal generator, and the corresponding output signal is tested according to the regulation.

This debugging and testing method can not effectively carry out complex logic debugging (such as PID adjustment, closed-loop logic control debugging, etc.) but also because of the complexity of hardware operation.

Sex also leads to low efficiency of logical debugging. In addition, the traditional logic debugging method needs the support of hardware devices such as controller, IO card, bus, network and so on. It is impossible to debug hardware devices when they are not fully matched during the logical configuration period; moreover, frequent short connection operation of hardware also has a certain impact on the service life of hardware. In view of the shortcomings of traditional testing methods, this paper proposes a method of using virtual DCS controller instead of physical controller in logic debugging. Virtual DCS controller can directly download and run DCS configuration engineering. Its system architecture and execution environment are very similar to real DCS system, so it can achieve a high degree of simulation and can effectively complete the logical debugging of configuration functions. Because the virtual DCS controller does not need the support of hardware devices and can be iterated with the engineering configuration, the virtual DCS controller is widely used in the debugging process of the DCS prototype for the logical debugging of the configuration engineering. Using virtual DCS controller, debugging engineers can easily debug subsystems monotonously and multi-system; moreover, virtual controller and simulation DCS layer 0 can interact with data through TCP/IP protocol, without concern about how to convert computer digital signals into physical signals (such as voltage, current and resistance signals) recognized by the controller board. And so on. The virtual controller management program provides an on-line debugging interface for data monitoring, which can cooperate with graphical debugging tools to complete dynamic debugging of configuration engineering. The data monitoring function of the virtual controller manager is shown in Figure 1.

Figure 1 (1) shows the data monitoring function of the virtual controller. The interface monitors the real-time value of the variable K3RCV004MP (the variable is the acquisition value of the virtual IO card, which is 11.979914MA and the range is 4-20MA). Fig. 1 (2) is the configuration logic of the down-drain regulating valve in the Chemical and Volume Control System (RCV). The down-drain regulating valve regulates the down-drain pressure of the main coolant system according to the set pressure (2.5 MPa in this working condition). The pressure measuring point RCV004MP is located in front of the discharge regulating valve and its range is 0-5MPa. It is converted to 4-20MA current signal in data acquisition. The variable K3RCV004MP_AV is the interface variable of the corresponding sensor in configuration logic (it is transformed from the variable K3RCV004MP through the IO algorithm firmware library range) (the range conversion formula is K3RCV004MP_AV= (K3RCV0). 04MP.MU-K3RCV004MP.

MD)* (K3RCV004MP-4)/(20-4) should be 2.493723MPa according to the current working condition, and the real-time value in the configuration logic should be 2.49MPa.

The online debugging function of the virtual controller manager is shown in Figures 2 and 3. Through the pressure value of RCV004MP, which is the pre-test point sensor of the regulator valve forced by the virtual machine, the PID and the regulation status of the regulator valve are checked.

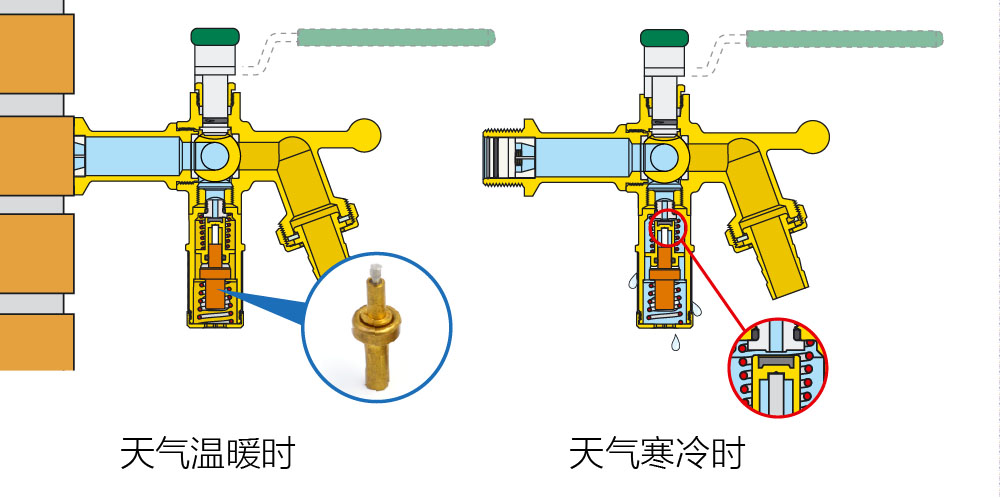

When the mandatory input value is 4MA, as shown in Figure 2 (1); through range conversion, the input value to the PID is 0MPa, as shown in Figure 2 (2); after calculation, the output value of the PID is 0%, which is transferred to the DCS 0 layer (equipment model) through the communication interface software, and the valves are gradually closed to 0%, as shown in Figure 2 (3). When the compulsory input value is 20MA in the virtual machine, as shown in Figure 3 (1); through conversion, the input value to the PID is 5MPa, thermostatic element as shown in Figure 3 (2); after calculation, the output calculation value of the PID is 100%, and then through the communication interface software to the DCS 0 layer (device model), the valve gradually opens to 100%, as shown in Figure 3 (3).

This means that the input/output variables and intermediate variables can be set in real time during the operation of the system, and the input, output and arbitrarily selected variables can be monitored online in real time. Moreover, the dynamic debugging of the configuration engineering can be completed with the graphical debugging tool of the DCS prototype system.

In the process of prototype debugging, the default is that all systems are debugged with virtual controllers. After each logical debugging of subsystems (such as RCV systems) is completed, the debugged configuration engineering (configuration engineering in virtual controllers) is loaded into the corresponding physical controllers, and then other systems are debugged in virtual controllers. After the configuration engineering is downloaded to the physical controller, multi-system debugging is needed, which involves the switching of virtual and real controllers, that is, some controllers are switched from virtual to physical. After switching, the simulation DCS layer 0 data will be redirected to the physical controller, and the communication between stations and the data interaction to the DCS layer 2 will also be transferred from virtual to physical. Because the traditional logic debugging is carried out on the actual controller, the complex logic debugging can not be carried out efficiently. This paper presents a method of using virtual DCS controller instead of physical controller in logic debugging. The advantages of this debugging method are as follows: 1) the debugger operates the virtual DCS controller software, and the signal injection is equivalent to the assignment of variables, which makes the operation simple and efficient; 2) the virtual DCS controller software is easy to access the device model of power plant (through TCP/IP communication for variable communication), so it can be responsible for logical debugging.

The virtual DCS controller can be directly downloaded and run the DCS configuration engineering, and its system architecture and execution environment are very similar to the real DCS system. The actual debugging results prove that DCS virtual machine can effectively complete the configuration logic debugging and improve the debugging efficiency.