In the process of the continuous development of social economy and technology, WiFi transmission communication technology and 3D printing technology are also constantly developing.

At present, 3D printing technology has been widely used in education, aerospace, medical and defense fields. However, the current 3D printers still use traditional and effective printing methods, which need to be equipped with a series of devices, such as computers, so it is inconvenient to carry them. In order to solve this problem, the wireless 3D printer controller based on WiFi technology is studied, so that printing can be separated from the computer, realize wireless mobile printing, and facilitate the use of users and related personnel. D printing has become a rapid prototyping technology. Its main basis is digital model files, using powder metals or plastics and other materials to create objects through layer-by-layer printing. But now most of the 3D printers are printed by connecting computers or using storage devices, which is very inconvenient for users. Now tablet computers, mobile phones and other mobile devices have become a common commodity in people’s lives, and these devices have the function of WiFi wireless transmission. Based on this, we can design 3D printing control equipment through WiFi wireless transmission communication technology, which is not only convenient for users to use, but also saves costs. STM23 is chosen as the core CPU of control, which requires that the control system can receive and transmit data of WiFi module. The controller can also read the 3D model data file in the storage device, control the stepping motor, control the hot bed temperature and so on. The following picture shows the design of WiFi-based wireless 3D printer controller. It can be seen from the figure that the control software in the mobile phone replaces the computer, and can transmit the print command and data to the 3D printer controller through the mobile phone WiFi. The controller can transmit the information of the printer status and the thermal damage temperature to the mobile phone, and display it, so that users can see it intuitively. The main control chip of the WiFi module in this paper uses ESP model.

The structure of this model WiFi module is relatively simple, and the price is affordable.

The AT instruction efficiency is high, and the development is more convenient. The network solution of this type of main control chip is relatively complete, so only a small number of external circuits can be realized, and the circuit occupies less space in PCB. It can connect the user’s physical equipment with WiFi wireless network, and realize the communication between LAN and Internet. WiFi communicates through controller and UART. In the process of 3D printing, the temperature of hot bed and extrusion head should be kept constant.

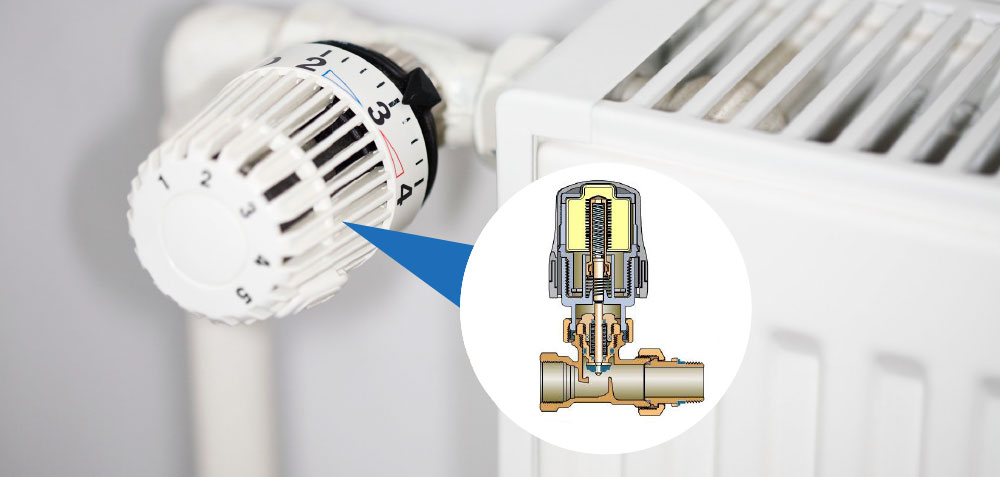

When using PLA printing material, the temperature of extrusion head should be between 175 200 and that of hot bed should be between 40 60 respectively. The temperature of extrusion head and the temperature of hot bed should be determined according to the actual environment. If it is a small printer, most of them will use two-phase four-wire stepper motor. The control of stepper motor can be realized by motor drive in the motor. Stepper motor drive in 3D printer generally uses A49 chip, which has a maximum of 16 subdivisions and a maximum output current of 2A. To improve the heat dissipation of the chip, the DRV88 stepper motor can be used to drive the chip. The maximum driving current is 2.3A and the maximum subdivision is 32. And the circuit in the chip has a certain protection function. If the printer fails, it can detect it in time, and quickly cut off the H bridge to protect the motor and driver chip. Mobile applications are required to select printed files, determine the status of printers, and confirm WiFi connections. Using Android as an application program, it can read printed data files, control WiFi to transmit data, set the temperature of the printer’s hot bed and print head, receive the temperature of the hot bed and print head, display the temperature data, and display the type of information and materials used. The flow chart is as follows: (1) Selecting the documents that need to be printed through the front page of the application program and entering the preview interface; (2) Confirming the preview and starting printing, pausing can be selected in the print interface, and the status of the printer can be displayed, including speed, extrusion head temperature, hot bed temperature and so on. The software of the wireless 3D printing controller includes the functions of controlling communication signal, digital signal, data processing and reading. The flow of the software program is as follows: (1) confirming whether the printer terminal has completed the initialization of the relevant modules such as motor, WiFi, heating, etc. If the initialization is completed, it must wait for the mobile terminal to send out the signal that needs printing; (2) confirming whether the printer terminal has completed the initialization of the relevant modules such as motor, WiFi and heating. If the mobile terminal sends out a signal that needs to be printed, after receiving the signal at the receiving end, it must accept the data. In order to save time, when receiving the printed data, it can preheat the temperature of the hot bed and the extrusion head; (3) After receiving the data, and the temperature of the hot bed and the extrusion head reaches the preset value, it can start printing. A series of information, thermostatic element such as the printer’s status, can be displayed in the application software of the mobile phone until the printing is completed.

With the continuous development and popularization of mobile terminals, such as mobile phones, flat panel, 3D printers and so on, the use of mobile terminals to control 3D printers is the future development trend. Based on this, this paper realizes the wireless printing technology according to the workflow of the 3D printer. Using STM23 microcontroller, it can effectively improve the processing efficiency and speed of the printer, keep the temperature balance, reduce the uneven thickness and broken wire and other undesirable phenomena, thus effectively improve the quality of printing. Through practical practice, the printer can be controlled by the terminal device of the mobile phone.