To be concise, fuzzy control is a simulation of human thinking.

Fuzzy logic can help reasoning operation and be applied to control equipment or automation work. In the research of automatic control field, the use of fuzzy control is a hot topic. It is of great significance for the development of PLC technology to adopt fuzzy control with programmable controller PLC. Once the fuzzy control is feasible, it will greatly strengthen the only degree of the former programmable controller. In the past, the control system relied heavily on the mathematical model of the controlled system.

The advantage of fuzzy control is that it can realize reasoning and judgment by using only fuzzy theory and professional knowledge without relying on rigorous mathematical model. For the programmable controller, it has to deal with more and more complex control objects, so it is necessary to adopt the method of fuzzy control. Programmable Logic Controller (PLC) as an electronic system for digital operation in industrial environment is generally referred to as PLC or PC. With the development of computer technology and electrical control technology, programmable controller (PLC), the core of microprocessing, has been derived, which includes information, communication and automation. It uses programmable memory to execute instructions for storage logic operations and sequential control, timing, counting and arithmetic operations, and controls various types of mechanical equipment or production processes through digital or analog input (I) and output (O) interfaces. In today’s era, programmable logic controller (PLC) is known as one of the three main technologies of modern industrial automation (CAD, PCL, robots) because of its technical advantages such as simple and flexible programming, low error rate and convenient maintenance.

Although programmable controllers have been widely used in industry, as the controlled objects become more and more complex, it is difficult for the former programmable controllers to keep pace with the development of the times. Therefore, it is necessary to develop new control modes to meet the needs of the times. The realization of fuzzy control method will greatly improve the quality of PlC control system, and it will become a new development direction of modern automation control system.

Fuzzy control (FUZZY) is based on the fuzziness of human thinking. Fuzzy control can be understood as the simulation of human thinking by the control system.

In the past control systems, the quality of the control system mainly depends on the accuracy of the control dynamic system. However, with the increasing complexity of the system and too many variable factors, it is difficult to accurately describe the control system in detail. In the previous development of control systems, engineers tried their best to simplify the system dynamics, but it was difficult to achieve the goal. Generally speaking, although the quasi-control ability of the former control systems is strong, it is difficult to describe the precise system. This is the core problem that fuzzy control wants to deal with. The definition of the human world can be said to be human perception. In the process of human perception, “fuzziness” can contain much more information than “clarity”, covering deeper connotations. Therefore, “fuzzification” has more “information storage space” and more human perception. Fuzzy control system can effectively refer to human’s control experience and imitate and describe human’s way of thinking.

That is to say, it can carry out pattern recognition, fuzzy reasoning and fuzzy decision-making to a certain extent in dealing with extremely complex things and systems, and finally realize fuzzy control, that is to say, it can accomplish tasks that were not tender in the past “precise control”, and fuzzy control. The technical soul lies in the use of “fuzziness” conditional sentences, which are generally programmed by technicians with certain professional abilities. Therefore, fuzziness can be said to be a very professional control and an outstanding manifestation of the development of human intelligence.

In practical work, our common fuzzy controllers are: single input single output, double input single output, multiple input single output, multiple input multiple output and so on. Because the fuzzy control is the imitation of human expert’s thinking and judges according to human’s thinking habits, there is no need to establish precise mathematical model for the controlled object in the control. Only need to sum up the control habits of the accumulated professionals, and formulate the relevant control rules based on these experiences, and finally form a fuzzy controller to achieve the establishment of the control system. The general steps of the algorithm of fuzzy control are as follows: firstly, the variables of the output and input of the controller are determined; secondly, it is necessary to establish a critical rule base of fuzzy control and to fuzzify the input and output. Finally, the input value of the variables and the fuzzy control rules are used, and the Larsen reasoning method is adopted to obtain the required fuzziness. Control the query table. These processes can operate normally under manual operation. In the practical application of fuzzy control, two-dimensional fuzzy controller is generally used.

Its principle is that the input is a set deviation variable and the deviation change rate, and a certain weighting factor is set. In this paper, the method of realizing fuzzy control by programmable logic controller (PLC) is also aimed at two-dimensional fuzzy controller. When determining the number of output domains, the accuracy of fuzzy control can be improved by subdivision level.

But at the same time, it should be noted that this will increase the calculation of control, and its subdivision accuracy will be limited by the word length of the memory. As far as experience is concerned, it is better to set the fuzzy subset in the universe as one-half to one-third of the total number of elements, and then the coverage of the fuzzy subset in the universe is better. In this process, we define the domain scope of e, EC and U. As we all know, the control rules are the key core of the fuzzy controller.

Whether they are correct or not directly affects the performance of the controller. The number of them is also an important factor to measure the performance of the controller. After the domain scope is established, we can set the precision of the deviation x (t) and convert it from the actual range of change (a, b) to the variable y of (-6, 6), that is to say, we can quantify the deviation and establish the rules of fuzzy control. Generally, for the control rules with adjusting factors, the control rules can be adjusted by adjusting the weighting factors, then changing the deviation and the weighting degree of the deviation to the output.

But once the weighting factor is selected, it can not be adjusted and changed in the whole process of fuzzy control. So in the actual control, in the process of the operation of the fuzzy control system, the deviation amount and the weighted intensity requirement of the deviation deviation in the control rules will be changed under different control states.

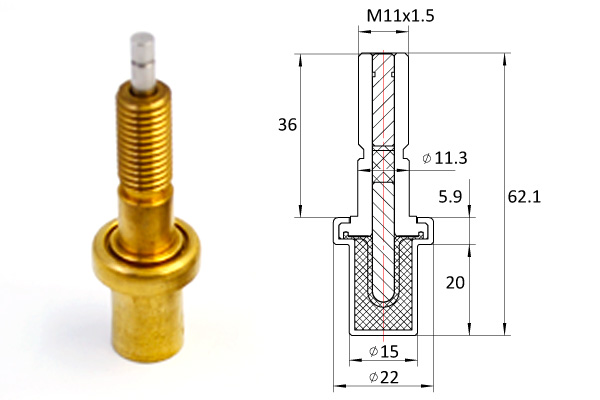

For two-dimensional fuzzy control system, thermostatic element when the deviation is relatively small, the fuzzy system is relatively stable, and the fuzzy control system is mainly a fast and stable system, that is, to reduce the system overshoot in the use process; but when the deviation is large, the main task of the system is to reduce and eliminate the deviation, which requires increasing the weight of the deviation.

In a word, different weighting factors should be considered when the deviation range is different, so as to realize the self-adjustment of control rules. The precise output of the control quantity is relatively convenient. That is, the fuzzy universe value is multiplied by the proportional factor of the control quantity to get the control value of the actual output, and then it is eventually transmitted to other controlled objects. Fuzzy control in PLC is the integration of fuzzy control technology and PLC technology. It not only includes the flexibility, reliability and practicability of programmable control system, but also increases the intellectualization of control system on these technical advantages, which greatly expands the development prospects of programmable control system. This paper briefly describes the research method of using fuzzy control to realize programmable controller PLC, hoping to give readers some reference value.