This paper mainly uses STC89C52 MCU to simulate the intelligent control controller of automobile taillights. Six LED lights are used to simulate automobile taillights. Six independent keys correspond to different states of right-turn, left-turn, normal and braking respectively. The temperature is measured by digital temperature sensor DS18B20, and the MCU accepts sensor output. After processing, LED is used. Digital tube realizes temperature value display. In the actual design of analog circuit, I added 74HC595 chip, which reduced the use of 51 single chip I/0 port. In the complex circuit, this is a good way to realize the advantages of a chip controlling multiple different circuits. In the actual design of analog automotive taillight control circuit, the characteristics of LED drive circuit are understood, the corresponding solutions are proposed, and the reliability design is carried out. In this design of analog automobile taillight control circuit, we can make good use of the function and application of 51 single chip computer we learned in the course, as well as C language programming, analog electronic circuit basis, and digital circuit basis. In practical application, there are many ways to design automobile taillight control. In this design of analog circuit, I STC89C52 single-chip computer is used as the design core of the whole circuit to control the analog function of the whole circuit.

The whole circuit becomes simple, intuitive, easy to make, and easy to operate. 51 single-chip computer can be erased repeatedly, and its performance is reliable. Automobile has become the most important means of transportation nowadays. It is not only a means of transportation, but also a symbol of people’s living standards.

Car lights are an indispensable part of it. There are two main functions of automobile lamp: one is illumination function, which can illuminate roads, traffic signs, pedestrians, other vehicles, etc. to identify signs and obstacles; the other is signal function, which shows the existence of vehicles and conveys the signals of vehicle driving status. Automotive lighting and signal devices are important safety components of automobiles.

Of the 105 European ECE regulations on automobiles, 36 are directly related to automotive lighting and signal lights. Among all kinds of automobile signal lights, taillights play a very important role and have a very close relationship with traffic safety. With the development of society, more and more automobiles have been used, which has become an indispensable means of transportation in people’s lives. Therefore, the safety of automobile taillights has attracted great attention, in which automobile taillights play an important role and are an indispensable part of automobile safety. Its existence greatly reduces the occurrence of traffic accidents. Therefore, as a warning light, the importance of automobile taillights is immeasurable. How to design and realize the various functions of automobile taillights is the design purpose of the control circuit of automobile taillights.

Now the design of automobile taillights is also full of patterns. It is not only changeable in appearance, but also greatly improved in function. To realize the function of automobile taillight control circuit, many different schemes can be adopted, which can be realized by using single chip computer, analog electronic technology, digital electronic technology and separation components. This design is realized by single-chip computer, at the same time, it increases the detection function of environmental temperature, avoids the damage of components caused by excessive temperature, and effectively prolongs the life of automobile taillights.

At present, the domestic automotive electronization competition is very fierce, and the application of electronic control system is more extensive. With the continuous improvement of single-chip computer and large-scale integrated circuit technology, the higher the electronic level of high-grade automobiles. The data show that among the famous foreign automobile manufacturers, the average cost of consuming electronic products per vehicle accounts for about 30% of the total vehicle, among which there are more than 50 optical microprocessors. The most prominent feature of automotive electronics is to promote the control system. At the end of 1990s, Columbia took electric lamps as headlights and taillights.

It was the first structure of taillights proposed by Columbia. On this basis, it gradually developed, including the light source and control system of taillights, mirrors, illumination mirrors and so on.

With the use of xenon lamps, driving safety and comfort have been greatly improved. With the development of science and technology, simulation designs have been adopted by foreign large car light control companies and Japanese small car light companies. Since 1990s, with the development of CAD and CAM technology, taillight circuit has been simulated and designed, and complex three-dimensional spatial light path calculation has been adopted. At present, the control circuit of automobile taillight is generally composed of hardware circuit structure based on microprocessor, but because of the limitation of hardware circuit, the function and performance of the circuit can not be changed at will, so it has brought some limitations to the development of automobile taillight control system. At present, automotive taillight control circuit is a very widely used equipment with high cost performance.

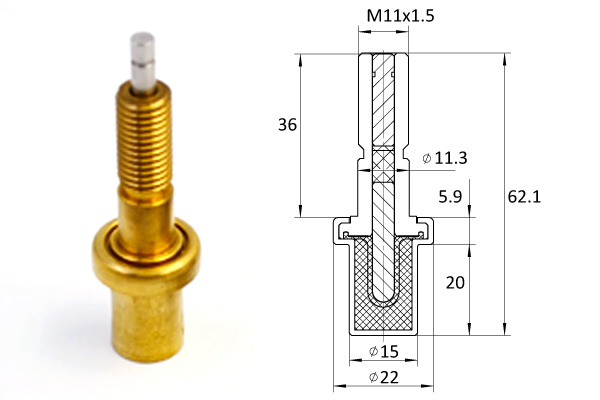

With the rapid development of automotive industry, thermostatic element the development of automotive control circuit is also changing with each passing day. Integration, lightweight, intelligent and beautiful have become the inevitable trend of automotive taillights and their control circuit.

Through this design, understand the circuit design process, we must first carry out analysis, starting from the module, to carry out the principle analysis of each module, and then have a full understanding of the working principle of the components used, and then start to design the schematic diagram of each module, the design process may have a variety of programs, according to the cost, according to the principle of the circuit design. The error, the difficulty of programming and other factors choose a more reasonable scheme. After the schematic design is completed, each module circuit and the whole design circuit can be simulated in the simulation software to realize the complete design from concept to product. According to different conditions, different simulations are carried out, and the simulation results and the results we need are compared, so as to know whether the circuit is reasonable or not. If it is not reasonable, we can find out the errors or change the design scheme. Finally, we can process and improve the circuit according to the designed circuit diagram, and make physical measurement experiments.

In this design, according to the design requirements, I use STC89C52 MCU to complete the design of automobile lighting control circuit. Using the abundant I/O ports of MCU and the flexibility of its control to achieve. After analysis, the automobile control circuit is divided into three modules: STC89C52 single-chip computer system, LED lamp array, recognition circuit and light emitting circuit. As a central processing system, the MCU detects the switch control signal executed by the driver according to the logic switch control, obtains the corresponding signal for transmission, and then receives the corresponding instructions, so that the LED lamp array sends out the corresponding instructions. The reason why the research scheme is adopted is that the hardware circuit is simple, the MCU program is direct, the operation is convenient, the material cost is low, and the system reliability is high. The design of the circuit by using MCU does not need other chips. It makes full use of the resources of MCU and can be widely used in various vehicles. Real-time detection of ambient temperature and display on the monitor. The automobile taillight control circuit system designed in this paper can reduce the hidden dangers of traffic accidents and improve the service life of the taillight circuit. The function of automobile taillight controller is to simulate six automobile taillights by six small LED bulbs, three on the left and three on the right. Four switches are used to simulate brake signal K1, parking signal K2, left turn signal K3 and right turn signal K4 respectively. When the car is turning, the MCU receives the signal and processes it. The three taillights on the side show periodic brightness and darkness. Temperature is measured in real time by temperature sensor of single chip computer. The control system of this single-chip computer takes STC89C52 as the controller and keyboard as the input signal. Because of the powerful function of STC89C52 itself, the driving of automobile turning lamp is accomplished by the driving function of single-chip computer.

The function of MCU is fully utilized, and the display circuit is output from parallel I/O port, consisting of current limiting resistor and light emitting diode. Low level makes light emitting diode turn on and off, which shows the corresponding signal lights, and achieves the control effect of left-turn, right-turn, brake and emergency lights. After the software part program starts, it enters the initialization, then scans the keyboard and waits for the key to press. If there are no keys pressed, it will scan all the time. If there are keys pressed, it will judge which key is, if it is 1 key, turn left; if it is 2 key, turn right; if it is 3 key, it will brake; if it is 4 key, it will run normally; if it is not pressed, it will detect the keys after executing the corresponding program, and if it is not pressed, it will keep the original state until the keys are pressed. Temperature module needs to accept key input. Through this course, I also learned a lot about electronic products. Further understanding of our real life electronic products, understanding and mastering the use of some simple electronic components, greatly expanding our knowledge. It improves the ability of doing things by oneself in the study and life in the future. It will give us great inspiration and help us to study, live and work in the future. In consulting materials, we have acquired a lot of additional knowledge and broadened our horizons. In the whole process of schematic design, using Proteus simulation, using Protel drawing, physical production, board debugging and so on, I have strengthened my ability to analyze and solve problems, and deeply realized that practice is the only criterion for testing truth. In a word, I benefited a lot from this course.