With the help of PLC programmable controller, it can provide important help for industrial production, realize the control and management of industrial equipment, comprehensively promote the control effect of industry, and provide the basis for industrial production automation.

Therefore, this paper analyses the industrial application of PLC programmable controller, analyses the control technology of PLC, studies the industrial application of specific PLC programmable controller, and aims to promote industrial production efficiency and promote the development of industrial enterprises.

The process of industrial production is complex and involves a wide variety of equipment. If we use manual operation and control, it will inevitably lead to inefficiency and frequent errors, which is not conducive to the development of industrial enterprises. The PLC programmable controller can meet the basic needs of industrial production and realize the braking control technology based on PLC. Moreover, the PLC can also be combined with other technologies to lay the foundation for intelligent industrial production. Based on this, this paper carries out the research and analysis of PLC programmable controller, and explores its specific application in industry. The details are as follows. PLC can be used in industrial production, it is a micro-controller, which can be widely used in automobile, chemical industry, manufacturing and other industrial activities. The control mode of PLC is simple, and it can well adapt to the industrial environment and meet the needs of industrial production. With the development of industrial enterprises, the level of industrial automation is constantly improving, and the intensity of research and development of PLC is also increasing, which makes the space occupied by PLC smaller and the control function more perfect, and has a very high development prospects.

In the specific application of PLC, the program needs to be programmed beforehand.

After setting is completed, the program can be executed with the help of the CPU inside the PLC. When all settings are completed, return to the first instruction, execute again and again until the user stops the program. In addition, in the specific work, the PLC can also collect the input signal and store it in the register, execute the order from left to right, after execution, enter the output processing stage, read the state associated with the output from the register, and then transfer it to the output latch, with the help of a specific way to achieve output control.

Make equipment to complete instructions. The PLC controller has good application value in practical application, and its characteristics are obvious. Now the specific characteristics of the PLC controller are analyzed in detail. The details are as follows.

Good reliability. PLC has a good application value in specific work, it can provide services in a variety of environments.

Its hardware and software have good anti-interference ability, and the circuit and CPU have chosen the way of electrical isolation. Moreover, in the specific industrial environment, the working environment temperature of PLC is relatively high, but in this environment, PLC still has good working ability, and the failure rate tends to zero. For the software part, the PLC has set up a monitoring program, which can realize the time monitoring of the operation of the PLC and reduce the generation of errors and redundant programs. The design of the system is simple. With the help of PLC to realize the construction of control system, it does not need too much equipment support, and no matter what kind of complex equipment, only need to pre-set control procedures, can realize the control of equipment, with simple and direct characteristics. Moreover, the use of PLC control can effectively reduce wiring workload, make maintenance more convenient and effective, and have a positive effect on industrial production. Excellent cost performance. It only needs initial investment, follow-up maintenance, can obtain good benefits. Among them, the purchase cost accounts for a large percentage, but the maintenance cost of follow-up use is not high, the maintenance time is not high, and it can be used repeatedly, with a good rate of return, in line with the actual needs of industrial production.

The application of PLC programmable controller in industry is mainly based on control. In order to meet the needs of industrial production, with the help of micro-computer technology and communication technology, it can achieve comprehensive computer control. It has good application value. The detailed analysis of specific industrial application of PLC is as follows.

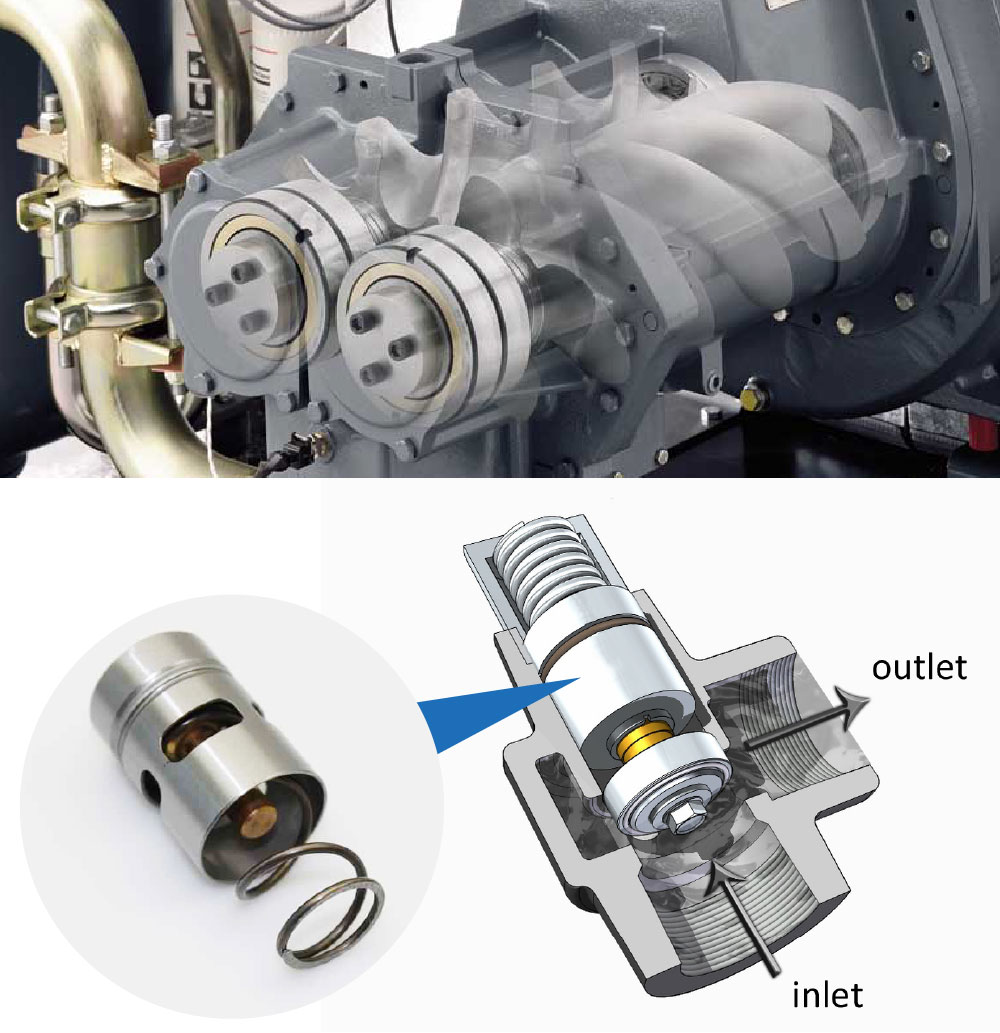

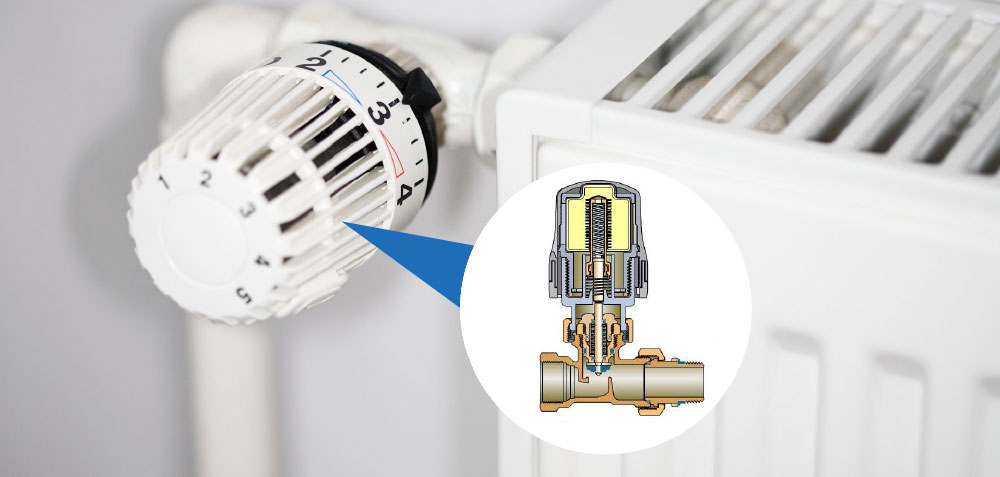

PLC is the most common application mode in industrial application. It can replace the traditional relay circuit, realize logic control, sequence control, etc. It can control a single device, and also can be used for the control of large-scale automation production line. It can guarantee the accuracy and reliability of switching quantity control of equipment. For example, in the production of mechanical manufacturing industry, the control of modular machine tools and grinders can be realized by PLC to promote the efficiency and quality of mechanical production. The control of analog quantity in industrial production is an important factor affecting industrial production. These analog quantities mainly include pressure, temperature, humidity, liquid level, flow rate and flow rate. The reliability of these analog quantities is directly related to the reliability of industrial production. If these analog quantities can not be guaranteed, it will lead to safety problems in industrial production. For example, the pressure problem, if the pressure exceeds the standard, may lead to explosion accidents. In the specific industrial process control, PLC adopts A/D and D/A conversion module and various control algorithm programs to achieve control, thermostatic element and with the support of these technologies, it can achieve closed-loop control of analog quantity. Among them, PID regulation is a common control mode, which can be used in specific boiler control to meet the needs of safe operation of the boiler. In the current industrial production, PLC has gradually replaced the traditional instrumentation control, and achieved good results in the control of secondary equipment in the specific industrial production. It can realize the state monitoring of secondary equipment and ensure the safety and reliability of industrial process. The combination of PLC and variable frequency speed control technology can realize the control of motor speed, improve the ability of motor efficient operation, and also realize the control of motor energy consumption reduction. The effect is remarkable. In the specific control, the PLC is installed near the motor. With the help of circuit connection and many debugging work, it is judged that the connection between the PLC and the motor is effective, and the motor can be started only after the qualification is confirmed.

Observe whether there is conflict between PLC and frequency control system, and judge whether it is safe to operate. In industrial production, the application value of industrial robots is remarkable. In order to achieve the smooth completion of the work of industrial robots, it can cooperate with the position control ability of PLC to achieve mechanical processing production. Taking the mechanical processing of mechanical manufacturing industry as an example, the required tool runs according to the set trajectory, so as to realize the processing and manufacturing of mechanical products.

In the position control of PLC, the pulse sent by PLC to the synchronous motor winding is used to control the speed of synchronous motor, and then the specific tool parameters are determined with the design of tool trajectory, so as to realize the automatic control of machinery and meet the basic needs of industrial production. In industrial production, the main purpose of centralized control is to find the fault point of industrial equipment quickly and timely, to achieve the rapid disposal of problems, and to ensure the reliability of industrial production. And PLC is the key to achieve centralized control. When controlling, PLC collects the time when industrial equipment completes the set procedure and the workload of industrial equipment in the specified time. If the difference between the operating parameters of industrial equipment and the data stored by PLC is found, and the difference exceeds the standard value, PLC sends out an alarm to prompt the staff to produce machinery. Accident. The application of PLC in industrial centralized control has a very positive effect on the development of industrial enterprises. It can effectively improve the safety factor of equipment operation and weaken the adverse impact of faults on industrial enterprises. Modern PLC has good computing ability, data transmission ability and information acquisition ability. After data acquisition by PLC, it can process data, store it in memory, compare it with reference value, and realize control. Moreover, with the help of communication function, information can be transmitted to other intelligent devices or aggregated into tables. PLC communication not only includes the communication between PLC and PLC, but also can communicate with other intelligent devices. At present, PLC has an effective communication interface, which can meet the actual needs of production, and then comprehensively promote the information transmission effect of industrial production and enhance the control ability of PLC. In this paper, the industrial application of PLC programmable controller is analyzed.

The principle and characteristics of specific PLC are analyzed in detail. Combined with the actual situation of industrial production, the industrial application of specific PLC programmable controller is analyzed in detail, and its application in specific data processing, communication, centralized control, position control and industrial process control is analyzed. With friendly man-machine interaction cross-section, improve the quality of PLC services, and actively promote the sustainable and healthy development of industrial enterprises.