Thermal Material Treatment: to crush, mix, pelletize and shape the thermal material into designed size.

For thermal material used below +30°C, it is required the whole process under -10°C environment.

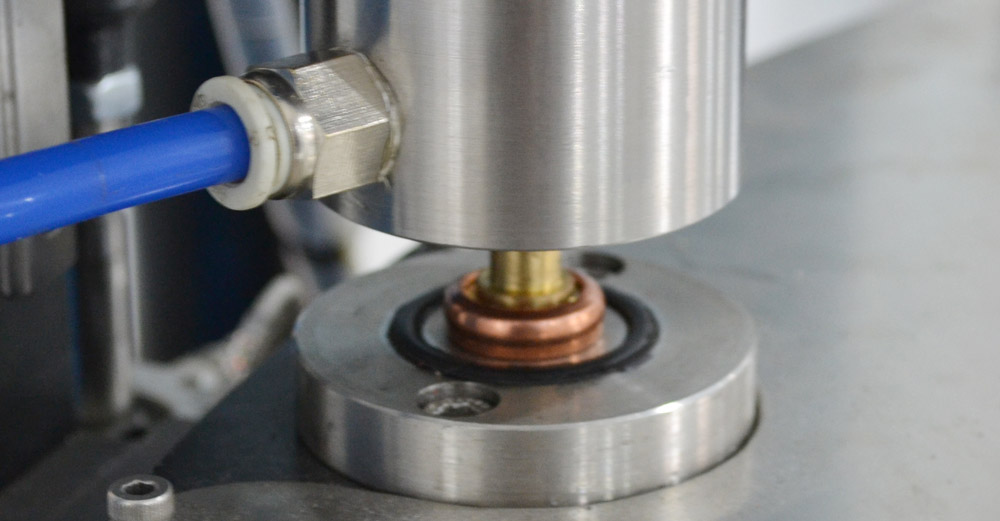

Element Riveting & Vacuum Machine: automatically rivet-sealing and vacuumizing for thermal elements.

Element Extrusion & Test Machine: automatically test and extrude the element body at required temperature, to achieve consistency. Max. test Temperature: +300°C.

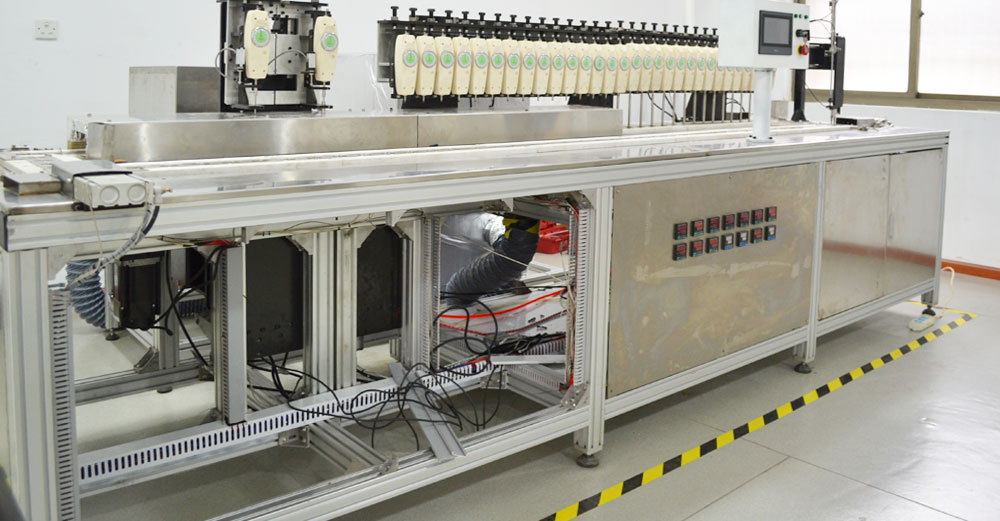

Auto End Sealing Machine and Leakage Tester: to seal the ending of T&P valve probe, with capacity of 10000 units per day in total; after end sealing, to examine leakage and pressure of T&P valve probe.

T&P valve Probe Complex Platform: all new T&P valve probe platform, with capacity of 12000pcs per day. Integrated function of assembling, rivet-sealing, vacuumizing and testing.

Thermal Actuator / Valve Complex Platform: to test actuators or valves’ pressure, leakage and temperature performance, under working condition.

Element Durability Tester: to test element temperature, pressure, rubber sealing, anti-decline, stretch strength and service life.

* Wisdom element already been passed 250000 times continuous test during 3 years.

High Precision Constant-Temp. Tester: to test elements’ temp-stroke data, and stimulate performance curve.

Test temp. range: -50 °C till +300°C, with resolution of 0.1°C.